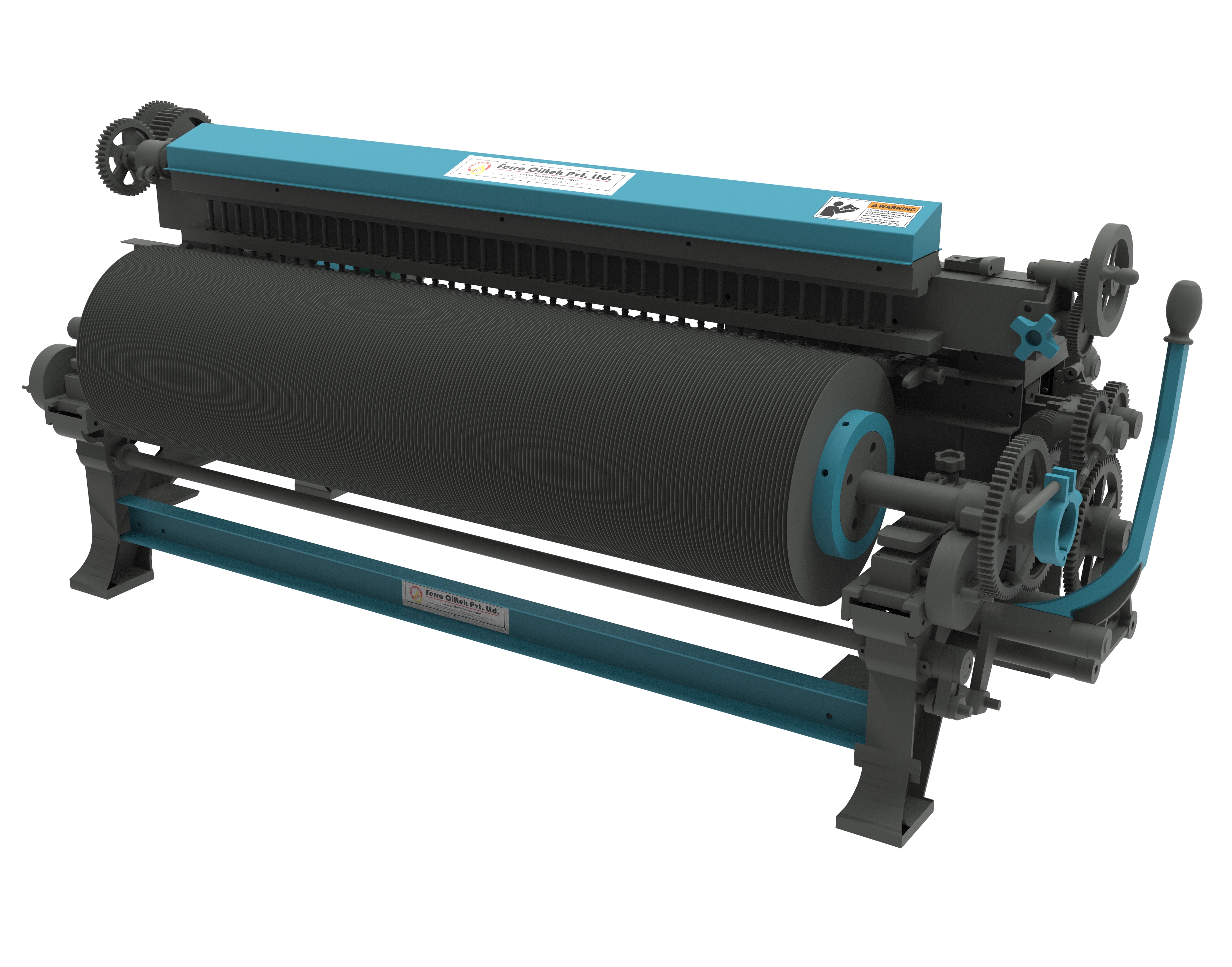

FX-176/200:

Saw Automatic Gummer

The FX-Automatic Gummer Machine is engineered to precisely sharpen the saw cylinder during each 24-hour operation cycle of the Delinter machine, ensuring consistent performance. Ferro's gummer is precisely made with all dimensional accuracy and seasoned SG Iron castings.

| Technical Specification | |||

| Model | Motor HP | Dimensions (L x B x H) | |

|---|---|---|---|

| FX-176 SAW | 2 HP | 1.9 x 1.2 x 1.2 mtr. | |

| FX-200 SAW | 3 HP | 4.1 x 1.2 x 1.2 mtr. | |

Note : The mentioned capacity depends on the input seed parameters.

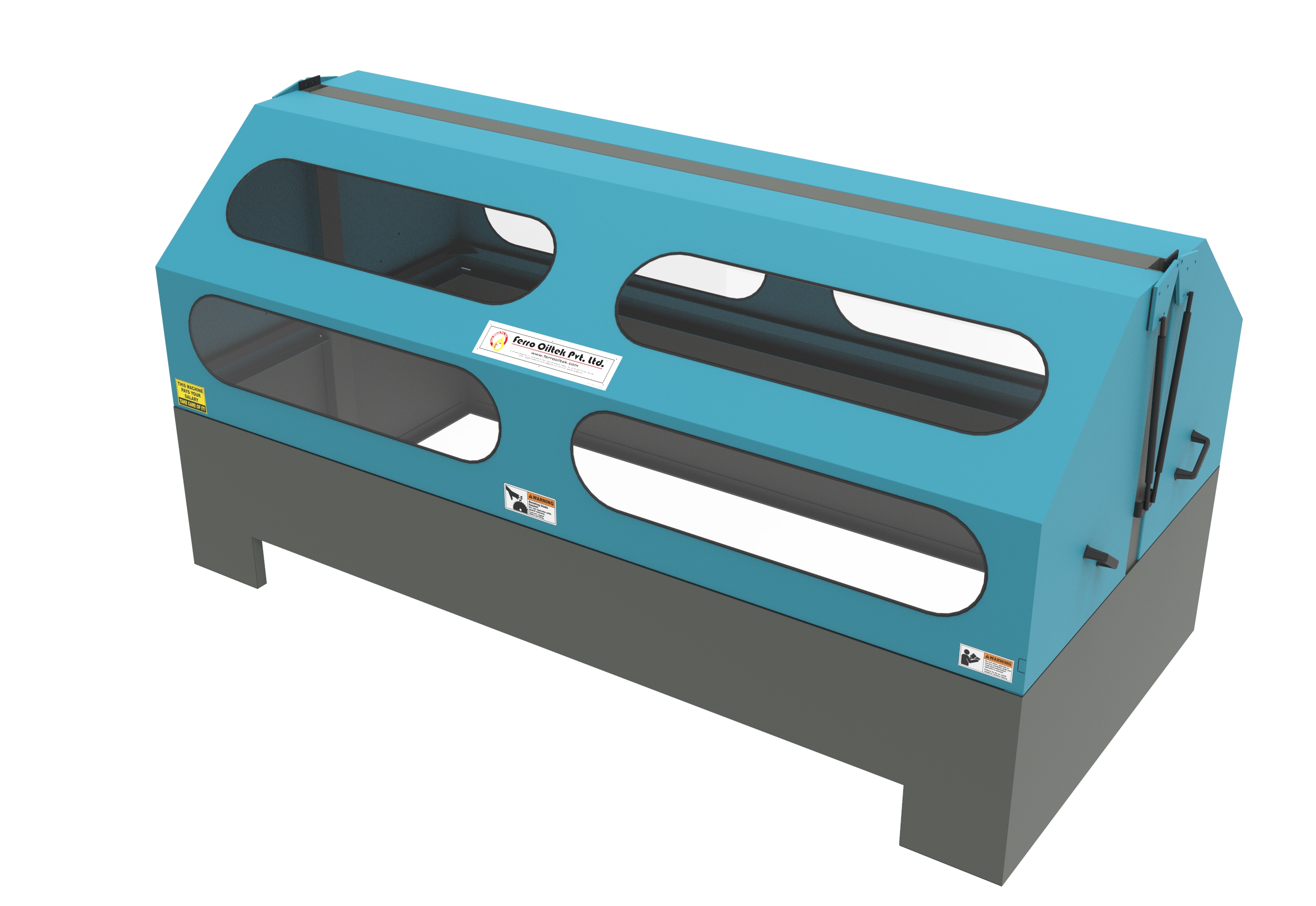

GUMMER MACHINE SAFETY ENCLOSURE (OPTIONAL)

The optional gummer safety enclosure protects the driving parts and clutch box, ensuring secure operations. It helps to reduce noise level. It features a two-way open, hydraulically operated guard for easy access and safety, along with four transparent acrylic windows for continuous observation during operation, illuminated by an LED light.

Key Features

New Gummer File Design: Enhanced saw sharpening efficiency is achieved with the new Gummer File's cutting-edge design, ensuring superior tooth profiles that boost delinting performance, reduce seed shattering, and extend the lifespan of saw teeth.

Precision Engineering: The Ferro Gummer machine is crafted with dimensional accuracy and durable, seasoned SG Iron castings for enhanced performance and longevity.

Fully Automatic Operation: The Ferro gummer machine operates automatically, ensuring precision and ease of use with minimal intervention.

Machine Tool Accuracy: Built with perfect machine tool accuracy for consistent, high-quality performance.

Interchangeable Parts Designed with interchangeable parts for low maintenance and effortless servicing, reducing downtime.

Special electrical panel configuration provision which not allowed to rotate the motor in reverse direction despite of wrong electrical connection.

Enhance equipment safety by using modern electrical techniques, including a phase sequence relay, to prevent breakage of gear tooth.

A sharp & uniform saw tooth profile plays a pivotal role in ensuring optimal lint quality and throughput; it is directly dependent on our Precise Gummer Machine.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.