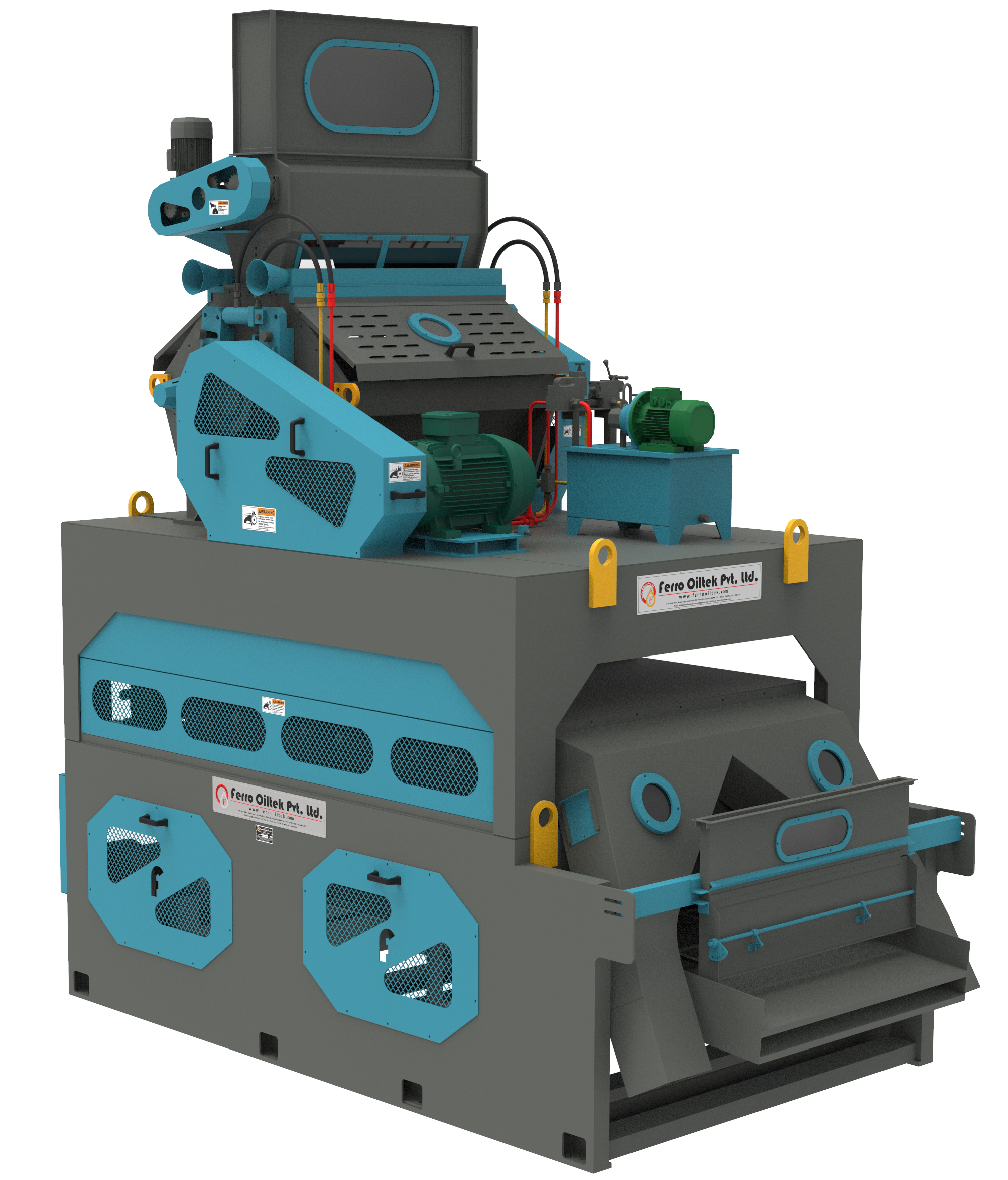

FX-48HCTRD :

High-Capacity Twin Roll Decorticator

The FX Series Decorticator efficiently dehulls oilseeds (Cotton, Soya, Sunflower, etc.) with minimal powder formation, enhancing production capacity and product quality. The equipment cuts seeds and separates hulls and meat with high efficiency, ensuring optimal results.

The FX Series Decorticator has the provision of heavy duty twin roll magnetic feeder, which avoid the entry of metal particles into the DC machine. The Decorticator drums is made by special graded cold roll alloy steel with interchangeable knife, provision of heavy duty shaft & it is also mounted on heavy duty bearing & housing.

With the use of an adjustable feed damper and regulated speed control gives accurate & reliable feed rate which results in consistency in machine output.

In The FX Series Decorticator, the process of hulling begins with an adjustable mattered roll feeder attached with powerful magnets designed to offer an absolute consistency and uniformity to the flow rate and also control the foreign particles.

| Technical Specification | ||||||

| Model | Capacity | Motor HP | Dimensions (L x B x H) | |||

|---|---|---|---|---|---|---|

| FX-36 HCTRD 100 | 100 | 47.5 HP | 4.0 X 2.0 x 3.9 mtr | |||

| FX-48 HCTRD 150 | 150 | 56.5 HP | 4.0 X 2.3 x 3.9 mtr | |||

| FX-48 HCTRD 200 | 200 | 73 HP | 4.0 X 2.3 x 3.9 mtr | |||

| FX-48 HCTRD 250 | 250 | 250 HP | 5.1 x 2.7 x 4.3 mtr. | |||

Note : The mentioned capacity depends on the input seed parameters.

Key Features

Heavy-Duty Twin Roll Magnetic Feeder : Ensures precise feed rate control for optimal accuracy and efficiency. Integrated rare earth magnets provide superior protection for downstream operations.

Made from special graded cold – roll alloy steel with interchangeable knives, mounted on heavy-duty shafts and bearings for long-lasting performance.

Automatic Hydraulic Protection System for Huller Drum and Knives :

The automatic hydraulic protection system safeguards the huller drum and knives from foreign particle damage. Pressure-sensitive components detect and expel particles, while the system resets automatically for continuous, low-maintenance operation.

The reengineered basket beater is precisely fabricated for easy maintenance and smooth opening and closing.

Self-Cleaning Screen :

Mounted on the tray to ensure hassle-free operation & prevent material buildup for consistent performance.

Heavy-Duty Eccentric System :

Engineered for the shaker tray to enhance durability, ensure smooth operation, and extend operational life.

Conveniently Positioned Motors

Electrical motors are strategically located for easy access and quick maintenance.

Zero Speed Sensors provision over basket beater ensure precise accidental monitoring for the compound drive system.

Safety guards with limit switches mitigate accident risks from rotating parts by triggering an instant shutdown if opened.

The use of VFD for twin roll feeder, main huller drum and basket beater ensures precise initial torque control during their operation.

Providing Inspection windows for clear internal separation visibility.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.