Agitators & Mixer

At Ferro Oiltek, we recognize that every mixing process has its own unique set of requirements. That’s why our agitators are engineered for flexibility and customization, making them ideal for a wide range of applications—from blending chemicals to handling high-viscosity substances. Industries rely on Ferro Oiltek’s agitators for their tailored configurations, including top-entry, side-entry, and bottom-entry designs, which cater to specific process needs. Constructed from robust materials like stainless steel and Hastelloy, our agitators are built to endure even the most demanding industrial environments. Moreover, their advanced impeller designs enhance energy efficiency and mixing performance, helping reduce energy consumption and lower overall operational costs.

Reactor Agitator

Designed for chemical reactors, this agitator ensures uniform mixing of reactants, proper heat distribution, and controlled reaction kinetics. It is built to withstand pressure, temperature, and corrosive environments.

Turbine Agitator

Ideal for mixing low to medium viscosity fluids. It features multiple flat or curved blades that create high shear and axial flow, suitable for emulsification, dispersion, and gas-liquid mixing.

Helical Agitator

Used for mixing high-viscosity materials like pastes, gels, and polymers. The helical ribbon or screw design allows smooth, gentle mixing and efficient movement of materials from top to bottom.

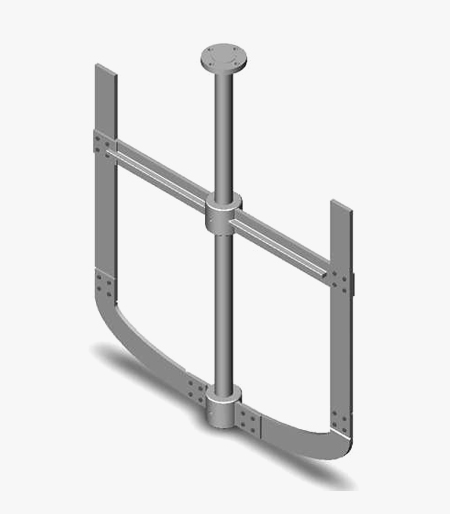

Anchor Agitator

Slow-speed designed for highly viscous products. Its sweeping motion scrapes the vessel walls ensuring complete mixing & heat transfer.

Paddle Agitator

Suited for uniform mixing of liquids and light pastes. The flat blades provide low-shear mixing, making it ideal for heat-sensitive or delicate materials.

Propeller Agitator

Best for low-viscosity liquids. The high-speed rotating blades generate axial flow, which is ideal for blending, solids suspension, and fast mixing operations.

- Accurate Mixing Performance : Featuring sophisticated speed regulation and specially designed impeller setups, Ferro Thermtek agitators ensure uniform and reliable mixing across all batches.

- Versatile Material Options : Available in a variety of construction materials such as SS304, SS316L, Hastelloy, and Titanium, our agitators are suitable for use with aggressive chemicals and high-temperature liquids.

- Optimized Impeller Variants : Ferro Thermtek provides multiple impeller choices—including axial, radial, and turbine types—each engineered to enhance efficiency and suit specific mixing requirements.

- Adaptable Installation Choices : Designed for compatibility, our agitators offer multiple mounting styles, allowing for easy integration into existing tanks or process systems.

- Adherence to Global Norms : Ferro Thermtek agitators are manufactured in line with international safety and quality regulations, ensuring dependable performance in demanding industries like pharmaceuticals, chemicals, and wastewater management.

- Power Output : Offered in a wide spectrum ranging from 0.5 HP to 100 HP, accommodating various mixing intensities and vessel capacities.

- Impeller Rotation Speed : Adjustable speed settings from 10 RPM up to 1,500 RPM, enabling fine-tuned control over mixing dynamics.

- Tank Volume Compatibility : Engineered for compatibility with vessels of all sizes—from compact laboratory setups to massive industrial tanks exceeding 100,000 liters.

- Material Selection : Available in corrosion-resistant materials such as Stainless Steel, Hastelloy, Titanium, and others, ensuring long service life and chemical compatibility.

- Seal Configurations : Options include mechanical seals, lip seals, and tailor-made sealing systems suited to specific process demands.

- Superior Mixing Performance : Ferro Thermtek agitators are optimized for quick, uniform blending, significantly cutting down process time while maintaining high-quality output.

- Application Flexibility : Suitable for multiple process requirements including blending, dissolving, homogenizing, suspending solids, and facilitating thermal exchange.

- Low Maintenance Requirements : Constructed using premium-grade materials and durable components, our agitators require minimal upkeep and are built for extended use.

- Energy-Efficient Operation : Specially engineered impellers ensure reduced energy usage while maintaining excellent mixing efficiency, resulting in long-term cost benefits.

- Tailored to Your Process : Custom options available, including impeller style, shaft dimensions, and mounting configurations, to precisely match process specifications.

- Chemical Manufacturing : Effective blending of chemicals, catalysts, and reagents to ensure homogenous mixtures and stable process conditions.

- Water and Effluent Treatment : Used in mixing, aeration, and flocculation processes, contributing to efficient treatment and improved water quality.

- Pharmaceutical Industry : Accurate and gentle mixing of active ingredients in pharmaceutical formulations, ensuring strict quality and compliance.

- Food and Beverage Production : Helps in combining ingredients uniformly while maintaining hygiene and consistency essential in food-grade processing.

- Mining and Mineral Processing : Ideal for suspending solids and mixing slurry in ore beneficiation and mineral recovery operations.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.