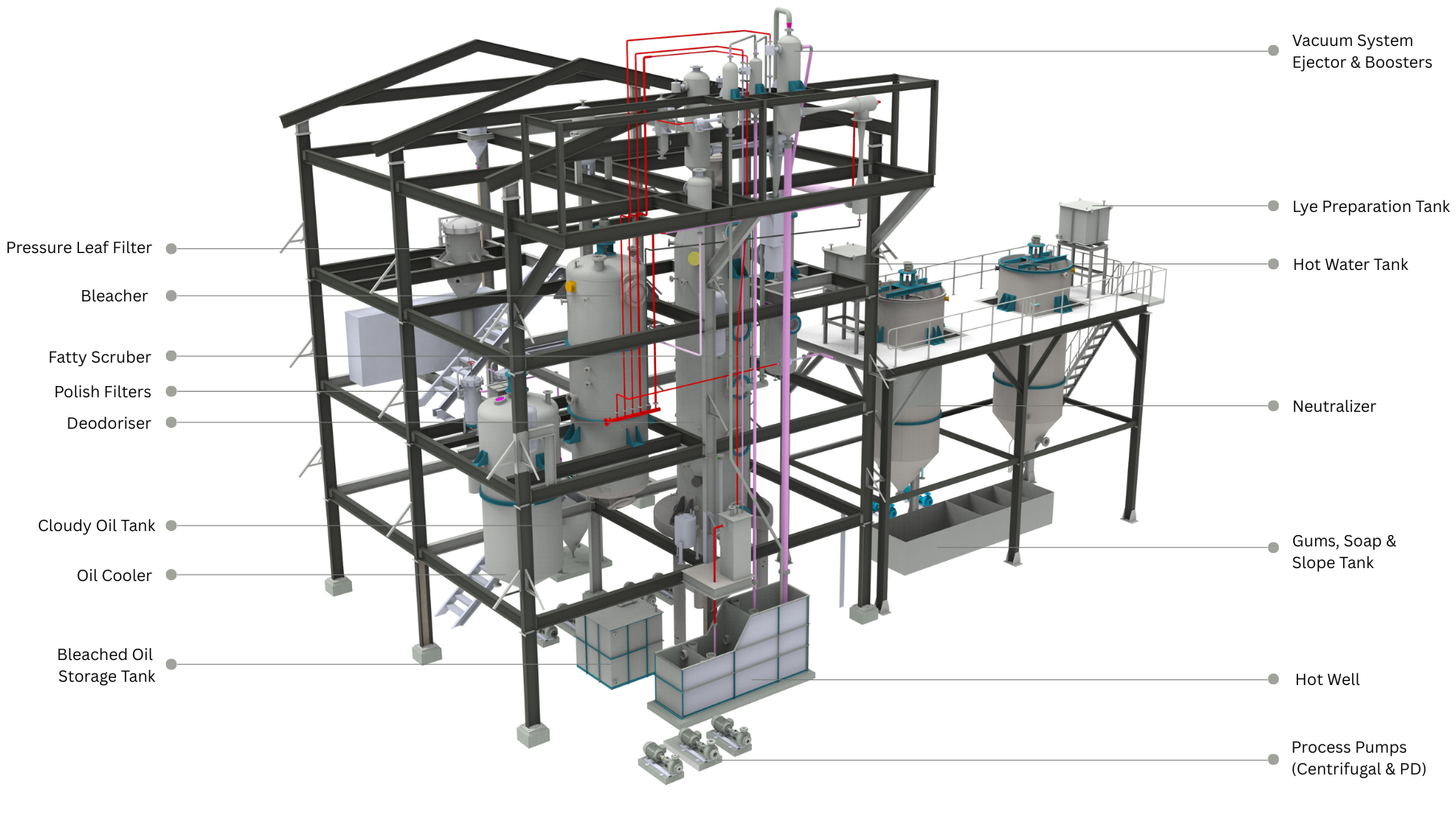

Ferro’s Batch Refinery

A reliable, cost-effective solution for your edible oil refining needs, offering high-quality performance and low maintenance! Converts crude oil into edible oil by removing unwanted minor components, ensuring minimal damage to the neutral oil and reducing refining losses. Designed for batch refining capacity under 30 TDP, typically operating in 3 batches per 24 hours. Batch process recommended due to low cost and ease of operation.

- Degumming/Neutralizing : Removes phospholipids and free fatty acids.

- Bleaching : Eliminates bad colour pigments.

- Deodorizing : Removes volatiles and free fatty acids.

- Dewaxing/ Fractionation : Eliminates waxes and triacylglycerols.

Advantages of Ferro's Batch Refining System:

Includes all necessary features and automation for efficiency and ease of operation.

Pumps and motors are sourced from trusted, certified vendors to ensure long-term durability.

FERRO 3D design ensures an optimized equipment layout in customized spaces, enabling a seamless plant setup that precisely mirrors the 3D design and actual commissioned plant.

Advanced Vacuum System: Steam ejector vacuum system replaces moving parts to compress gas, offering enhanced reliability and reduced mechanical wear and tear.

We offer fully automatic, semi-automatic, and manual plant solutions at an economical cost.

Easy-access manhole & hand hole for inspection and maintenance

Provide essential instrumentation package for utility control & equipment control to ensure optimal operating conditions and prevent damage.

High-temperature gaskets, precision-cut via water jet, ensure accurate profiles and eliminate leakage.

We provide self-cleaning visible inspection window over equipment with branded high illuminated light.

Pressure vessels & Heat Exchanger are tested for safety and reliability.

Robust Connecting Flanges : Engineered with high-strength, leak-proof bolted flanges to ensure secure connections, facilitate maintenance, and enhance system integrity under pressure conditions.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.