FX- Bleacher

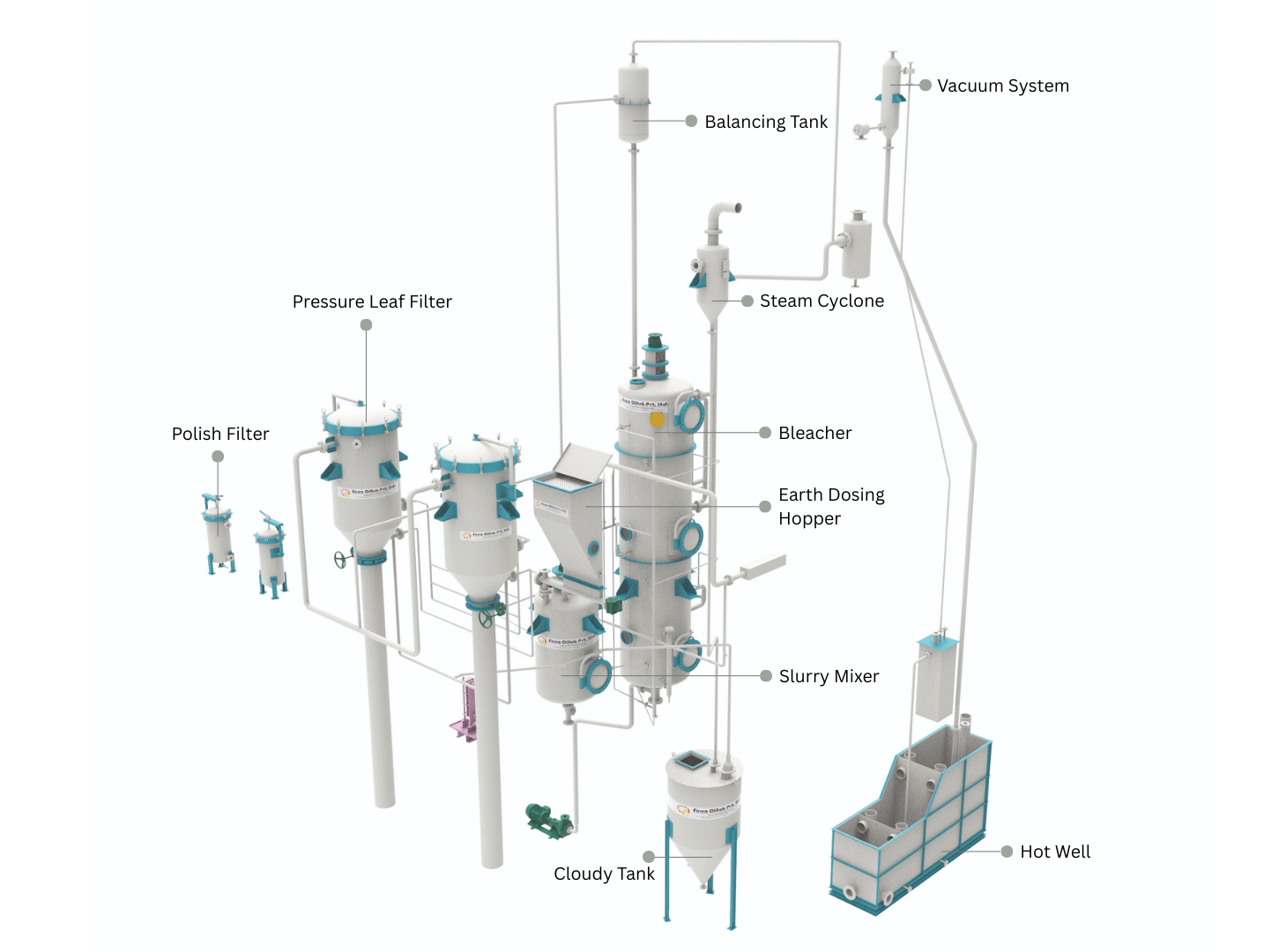

The advanced edible oil FX-Bleaching process uses high-efficiency adsorbents and controlled conditions to remove bad colour pigments, impurities, and oxidation products, resulting in best oil colour profile with improved stability and quality. Bleaching Section by Ferro includes- FX-Bleacher equipment, bleaching earth dosing hopper, set of Pressure leaf filters, Cloudy oil tank, Steam cyclone, Vacuum system, FX-Polish filters, Plate type heat exchangers and other accessories etc.

- Pigment Removal : Eliminate pigments such as carotenoids and chlorophyll to achieve the desired oil colour.

- Impurity Adsorptional: Adsorb and remove trace metals, soaps, phospholipids, and oxidation products.

- Oxidative Stability Enhancement: Improve shelf life by removing pro-oxidant compounds that accelerate oil degradation

- Flavor and Odor Improvement

- Preparation for deodorization and final refining stages

Advantages Of Ferro Bleaching

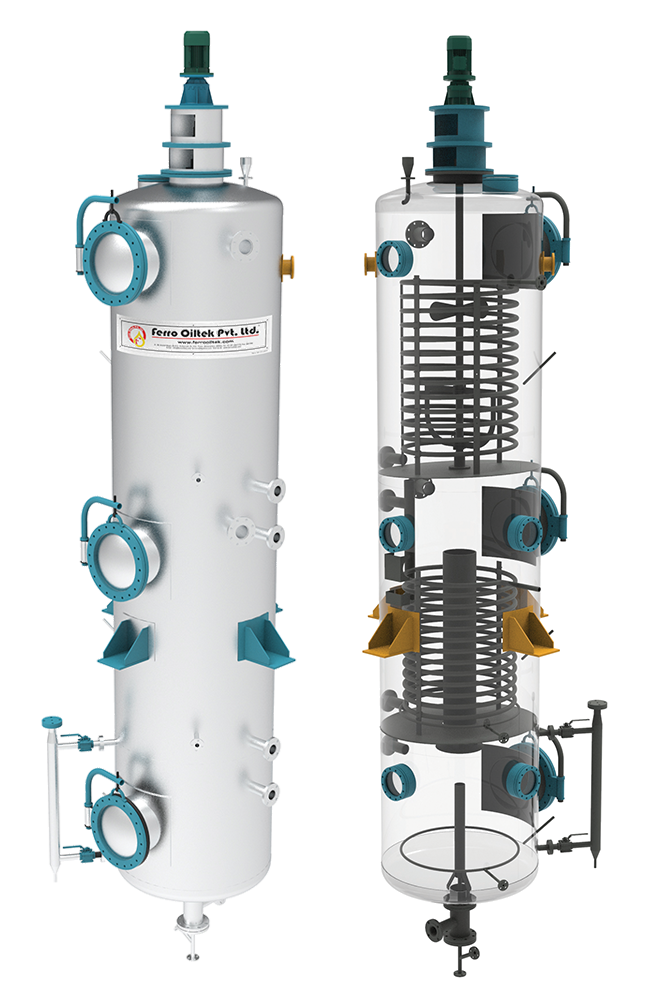

Constructed from SS-316 and SS-304 (customizable to customer specifications), Ferro's FX-Bleacher is designed for optimal bleaching performance.

A well-designed vacuum system with these features ensures bleaching efficiency results improve oil stability, minimal nutrient loss, and energy-efficient operations.

This pressure vessel is meticulously designed based on key parameters to guarantee efficient bleach-ability of the neutralized oil.

Flexible Capacity : Easily adjustable plant capacity within a defined range for optimal efficiency.

Comprehensive Safety Measures : Designed with thorough safety considerations for secure operation.

User-Friendly & Low Maintenance : Simple operation with minimal upkeep, ensuring long-term reliability.

Advanced Adsorbent Dosing System : Precise multi-stage dosing of bleaching earth, activated carbon, or synthetic silica enhances impurity removal while reducing adsorbent consumption.

Vacuum-Assisted Dry Bleaching : Operates under controlled vacuum to prevent oxidation, enhance bleaching efficiency, and improve filtration performance.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.