FX-Chain Conveyors

Chain conveyor is a heavy-duty material handling system that uses a chain to transport bulky, heavy, or awkward materials through various applications (Automotive industry, Heavy material transport, Mining & bulk material handling, Food Industry, Packaging & distribution etc.

Types of Chain Conveyors:

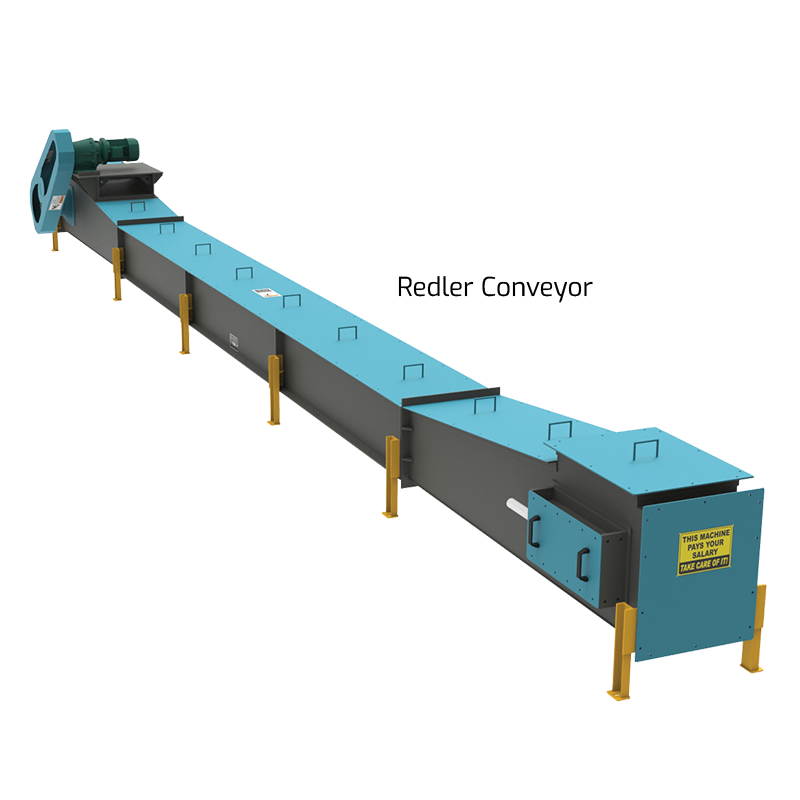

- Horizontal Chain Conveyors (Redler Conveyors): Suitable for bulk materials.

- Inclined Chain Conveyors (Bulk Flow Conveyors) : Efficient inclined transport with high capacity.

Key Features

Engineered for low maintenance and high reliability, making them ideal for extreme industrial conditions.

Modular design allows for flexible layout configurations to accommodate various plant layouts.

Round-bottom design ensures complete cleanout, preventing material buildup and reducing contamination risks.

Explosion-proof options available for hazardous environments, ensuring compliance with safety regulations.

Optimized chain and sprocket configurations reduce wear and enhance longevity, even under high-load applications.

Consider all safety features (sensors & alarms, Emergency stop and rotating parts safety guard)

High-quality Timken, SKF, NTN, FAG, NSK, and Schaeffler bearings ensure optimal chain tension, smooth operation, and durability with minimal maintenance.

Provide smoothly operated Tensioning and take up mechanical arrangement

UHMWPE enhances wear resistance in drag chain conveyors by reducing friction, minimizing material buildup, and extending component lifespan. Its self-lubricating, impact-resistant properties ensure smooth operation with minimal maintenance.

Technical Specification of FX-Horizontal Chain Conveyors (Redler Conveyor)

| Technical Specification | |||||||||||||||||||

| Model | Conveying speed | Unit | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.225 | 0.25 | 0.275 | 0.3 | 0.325 | 0.35 | 0.375 | 0.4 | 0.425 | 0.45 | 0.475 | 0.50 | 0.55 | 0.60 | 0.65 | 0.70 | m/s | ||

| FX-MH-RC7/14 | Q | 21 | 24 | 27 | 29 | 32 | 35 | 37 | 40 | 43 | 45 | 48 | 51 | 53 | 59 | 64 | 69 | 75 | m3/h |

| FX-MH-RC10.5/14 | Q | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | 64 | 68 | 72 | 76 | 80 | 88 | 96 | 104 | 112 | m3/h |

| FX-MH-RC11.5/18.5 | Q | 48 | 54 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | 101 | 107 | 113 | 119 | 131 | 143 | 155 | 167 | m3/h |

| FX-MH-RC13/20 | Q | 62 | 69 | 77 | 85 | 92 | 100 | 108 | 116 | 123 | 131 | 139 | 146 | 154 | 170 | 185 | 200 | 216 | m3/h |

| FX-MH-RC16/20 | Q | 75 | 84 | 93 | 103 | 112 | 121 | 131 | 140 | 149 | 159 | 168 | 177 | 187 | 206 | 224 | 243 | 262 | m3/h |

| FX-MH-RC20/20 | Q | 93 | 105 | 117 | 128 | 140 | 152 | 163 | 175 | 187 | 199 | 210 | 222 | 234 | 257 | 280 | 304 | 327 | m3/h |

| FX-MH-RC25/26 | Q | 123 | 138 | 153 | 169 | 184 | 199 | 215 | 230 | 245 | 260 | 276 | 291 | 306 | 337 | 368 | 398 | 429 | m3/h |

| FX-MH-RC31.5/26 | Q | 196 | 221 | 245 | 270 | 294 | 319 | 343 | 368 | 392 | 417 | 441 | 466 | 490 | 539 | 588 | 637 | 686 | m3/h |

| FX-MH-RC31.5/31.5 | Q | 244 | 275 | 305 | 336 | 366 | 397 | 427 | 458 | 488 | 519 | 549 | 580 | 610 | 671 | 732 | 793 | 854 | m3/h |

| FX-MH-RC40/26 | Q | 245 | 276 | 306 | 337 | 368 | 398 | 429 | 460 | 490 | 521 | 552 | 582 | 613 | 674 | 735 | 797 | 858 | m3/h |

Technical Specification of Inclined Chain Conveyors (Bulk Flow Conveyor)

| Technical Specification | |||||||||||||||||||

| Model | Conveying speed | Unit | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.225 | 0.25 | 0.275 | 0.3 | 0.325 | 0.35 | 0.375 | 0.4 | 0.425 | 0.45 | 0.475 | 0.50 | 0.55 | 0.60 | 0.65 | 0.70 | m/s | ||

| FX-MH-BF8/12 | Q | 14 | 16 | 18 | 19 | 21 | 23 | 25 | 26 | 28 | 30 | 32 | 33 | 35 | 39 | 42 | 46 | 49 | m3/h |

| FX-MH-BF11.5/12 | Q | 22 | 25 | 27 | 30 | 33 | 36 | 38 | 41 | 44 | 47 | 49 | 52 | 55 | 60 | 66 | 71 | 77 | m3/h |

| FX-MH-BF13/16 | Q | 33 | 37 | 42 | 46 | 50 | 54 | 58 | 62 | 67 | 71 | 75 | 79 | 83 | 91 | 100 | 108 | 116 | m3/h |

| FX-MH-BF16/20 | Q | 54 | 61 | 68 | 74 | 81 | 88 | 95 | 101 | 108 | 115 | 122 | 128 | 135 | 149 | 162 | 176 | 189 | m3/h |

| FX-MH-BF20/20 | Q | 68 | 76 | 84 | 93 | 101 | 110 | 118 | 127 | 135 | 143 | 152 | 160 | 169 | 186 | 203 | 219 | 236 | m3/h |

| FX-MH-BF26/20 | Q | 86 | 97 | 108 | 119 | 130 | 140 | 151 | 162 | 173 | 184 | 194 | 205 | 216 | 238 | 259 | 281 | 302 | m3/h |

| FX-MH-BF26/24 | Q | 104 | 117 | 130 | 143 | 156 | 168 | 181 | 194 | 207 | 220 | 233 | 246 | 259 | 285 | 311 | 337 | 363 | m3/h |

| FX-MH-BF32/24 | Q | 131 | 148 | 164 | 180 | 197 | 213 | 230 | 246 | 262 | 279 | 295 | 312 | 328 | 361 | 394 | 426 | 459 | m3/h |

| FX-MH-BF32/28 | Q | 153 | 172 | 191 | 210 | 230 | 249 | 268 | 287 | 306 | 325 | 344 | 364 | 383 | 421 | 459 | 498 | 536 | m3/h |

| FX-MH-BF36/32 | Q | 194 | 219 | 243 | 267 | 292 | 316 | 340 | 365 | 389 | 413 | 437 | 462 | 486 | 535 | 583 | 632 | 680 | m3/h |

| FX-MH-BF40/40 | Q | 270 | 304 | 338 | 371 | 405 | 439 | 473 | 506 | 540 | 574 | 608 | 641 | 675 | 743 | 810 | 878 | 945 | m3/h |

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.