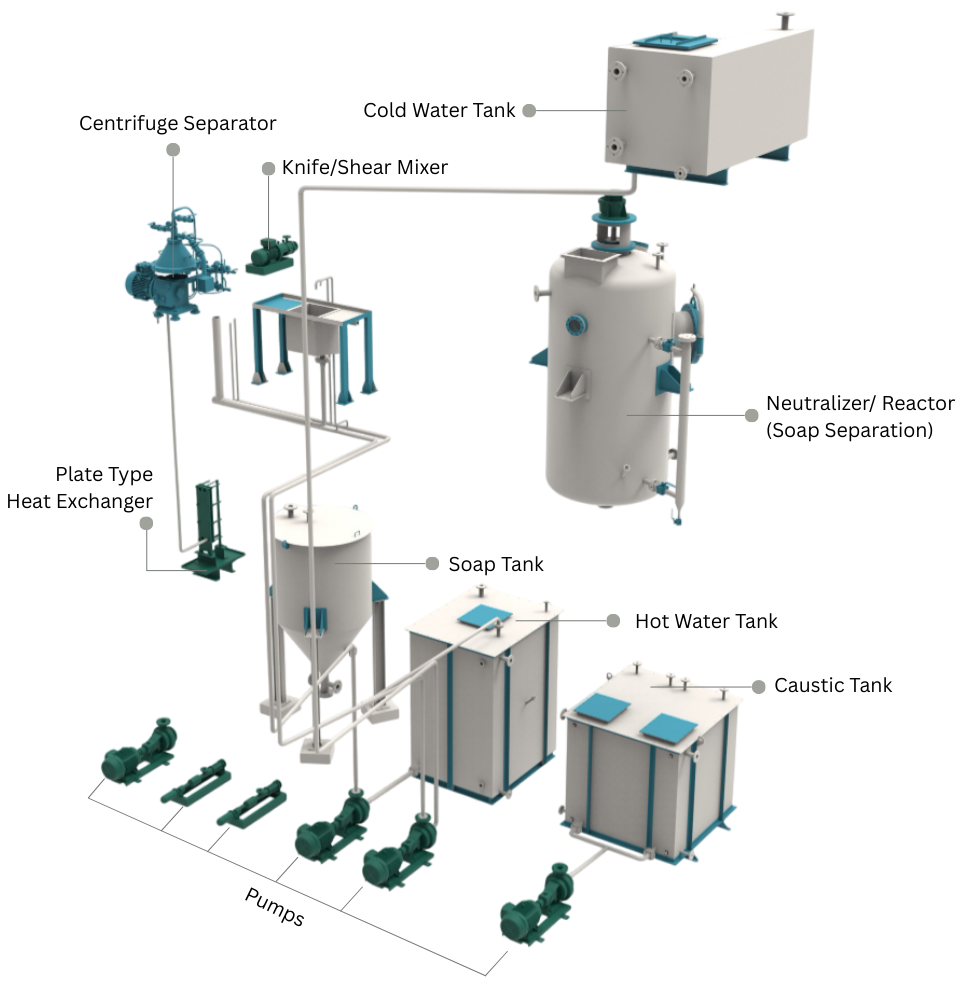

FX-Continuous Neutralization

The edible oil neutralization process converted free fatty acids into insoluble soap, impurities, and undesirable compounds from crude oil, enhancing its quality, stability, and taste for safe consumption.

- Removal of Free Fatty Acids

- Minimizing Potential Health Concerns

- Reducing Oxidation and Rancidity

- The core of this Neutralisation process is the soap-separating centrifuge separator, supplied by our trusted partner Macfuge, ensuring optimal output results and comprehensive after-sales service.

Advantages of Ferro Neutralization

Water-Efficient Technology : Consumes less water compared to competing machines, ensuring resource optimization.

Uncompromised Quality & Durability : Built with premium materials for all equipment, parts, and fittings, ensuring longevity & reliability.

Flexible Capacity : Easily adjustable plant capacity within a defined range for optimal efficiency.

Enhanced Safety Standards : All safety measures are meticulously integrated & adhered to for secure operations.

Certified & Tested Equipment : All vessels and components are rigorously tested and certified for durability and performance.

Easy-access manhole & hand hole for inspection and maintenance.

Provide essential instrumentation package for utility control & equipment control to ensure optimal operating conditions and prevent damage.

Variable Geometry Turbine in Macfuge Separator : Enables precise separation control, ensuring seamless operation and enhanced process stability for optimal performance.

Environmental Compliance & Sustainability : Reduced wastewater generation and optimized caustic consumption minimize environmental impact, ensuring regulatory compliance.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.