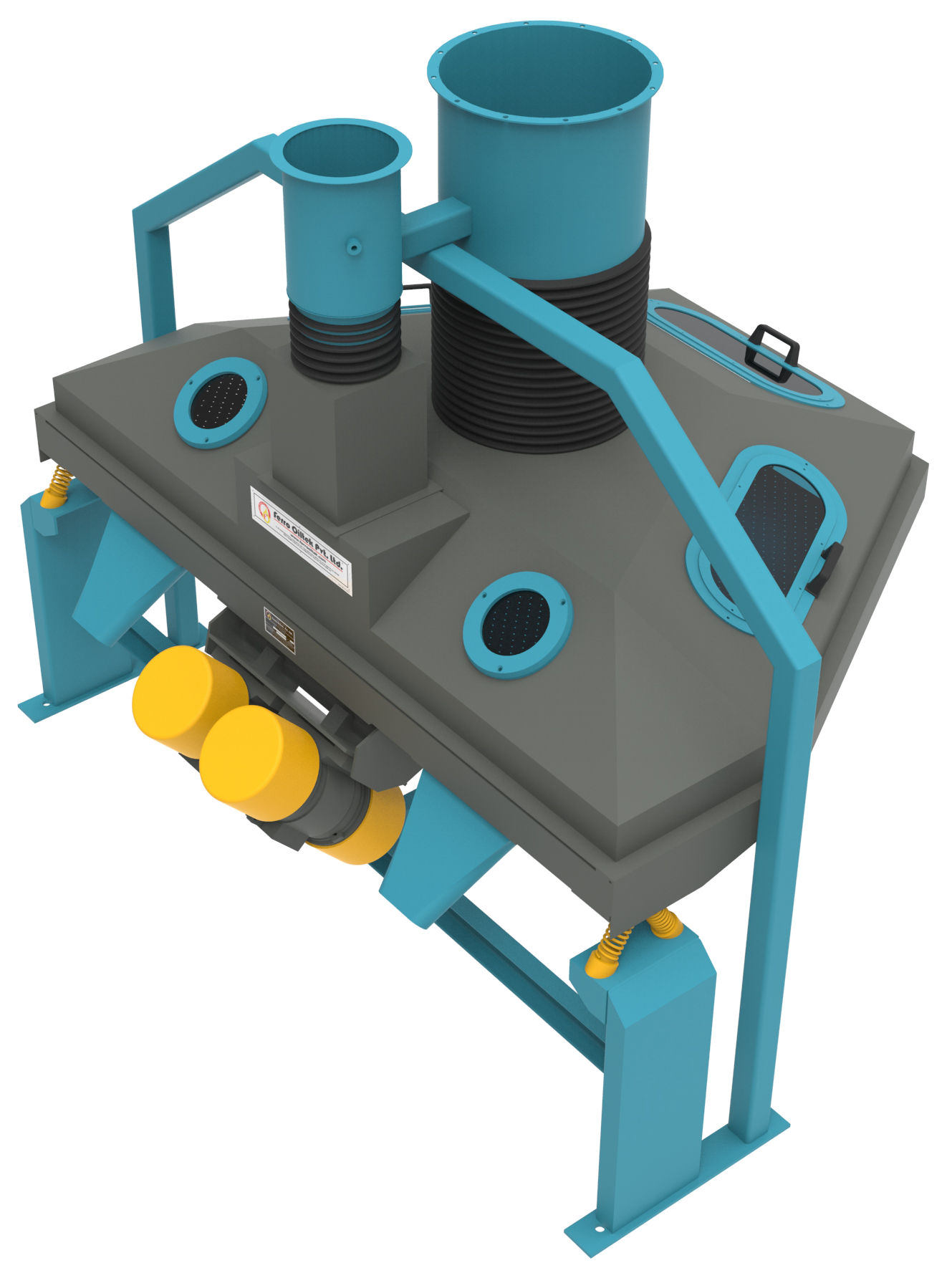

FX-DD : Dry Destoner

The FX-Dry Destoner is designed for the efficient removal of stones, glass, and other high-density foreign materials from oilseeds and various grains. Using precise air flow and vibration technology, it ensures clean, contaminant-free raw material, protecting downstream equipment and enhancing final product quality. Built for durability and consistent performance, it is an essential step in the seed and grain cleaning process.

Constructed with robust materials and designed for consistent, long-term performance, the FX-Dry Destoner is ideal for continuous industrial operations. Its user-friendly controls and low-maintenance design make it a reliable choice for processors who demand efficiency, durability, and top-quality results.

Application :

Variety of seeds, including soybean, sunflower, wheat, rape seed, caster seed, maize, grain, coffee, nuts, and adaptable for other oilseeds with custom modifications.

| Technical Specification | ||||||||||||||

| Model | Capacity | t/Hr | Dimensions (mm) | Allocated Power (KW) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wheat | Maize | Green Coffee |

Roasted Coffee |

Soya Bean |

Sun Flower |

L | W | H | D | d | Machine | Aspiration System |

||

| FX-DD-1 | 2.5 | 2 | 1.4 | 0.8 | 3 | 0.8 | 590 | 1220 | 1400 | 200 | 125 | 2x0.25 | 7.5 | |

| FX-DD-2 | 4 | 3 | 24 | 1.3 | 5 | 1.3 | 790 | 1220 | 1400 | 220 | 150 | 2X0.37 | 9.37 | |

| FX-DD-3 | 10 | 9 | 7 | 3.2 | 12 | 3.2 | 1650 | 1668 | 1835 | 360 | 200 | 2X0.37 | 11.25 | |

| FX-DD-4 | 15 | 12 | 10 | 5 | 18 | 5 | 2205 | 1668 | 1895 | 420 | 225 | 2X0.5 | 18 | |

| FX-DD-5 | 20 | 15 | 14 | 8 | 24 | 8 | 2500 | 1900 | 2250 | 450 | 250 | 2X0.75 | 22.5 | |

Note : The mentioned capacity depends on the input seed parameters.

Key Features

FX-destoner is capable of efficiently separating even small and light weight stone with the similar size of an oil seed & grain, thus ensuring optimal grain cleaning

Dry Destoner helps to improve the quality of the cleaned product by removing contaminants and ensuring high product safety assurance.

The machine is equipped with an aspiration unit to ensure a dust-free atmosphere in the processing area.

Special magnet plate is included in the Inlet feed cascade hopper to prevent metal pieces from entering the system.

The precise feed rate control ensures optimal accuracy, enhancing the overall efficiency of subsequent operations.

Easy-access door for vibratory tray inspection and maintenance.

Designed with a heavy-duty fabricated machine body frame.

User-friendly operation with simple adjustment.

In-house, FERRO designs specialized Vibro Motors, engineered with high-quality, heavy-duty windings to enhance motor durability and performance

Providing Inspection windows for clear

internal separation visibility

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.