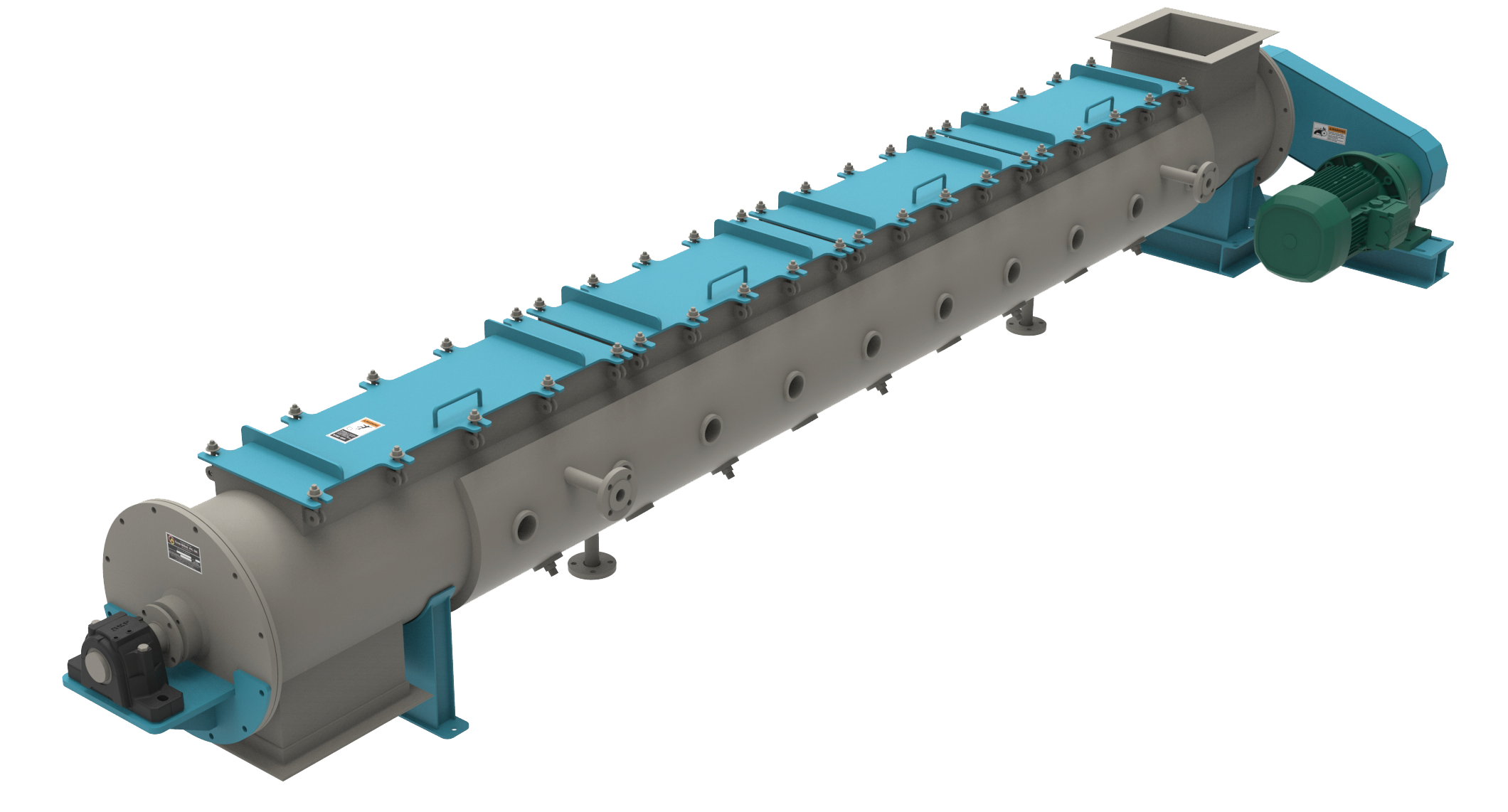

FX-FCD : High Performance Conditioner

Achieving high-quality oilseed flakes or meat preparation starts with precise thermo-mechanical conditioning. Proper conditioning ensures the ideal balance of moisture, temperature, and retention time, directly impacting extraction efficiency, pellet quality, and overall processing performance.

Our FX-Conditioner is designed to deliver consistent, uniform conditioning by incorporating advanced steam injection and efficient mixing. It allows for optimal moisture absorption and controlled temperature increase, ensuring the best possible material quality before further processing.

| Technical Specification | ||||

| Model | Conditioning Diameter X Length | Power (HP) | Capacity (MT/D) | RPM |

|---|---|---|---|---|

| FX-FCD1420 | 350 x 2050 | 5-7.5 | 100-125 | 30 |

| FX-FCD1620 | 400 x 2050 | 7.5-10 | 125-150 | 35 |

| FX-FCD1820 | 450 x 2050 | 10-15 | 150-250 | 35 |

| FX-FCD1826 | 450 x 2650 | 10-15 | 150-250 | 35 |

| FX-FCD183 | 450 x 3050 | 10-15 | 150-250 | 35 |

Note : The mentioned capacity depends on the input seed parameters.

Key Features

FX-Conditioner Specifically designed to condition the oil seed/ meat efficiently while preserving oil cells.

Precision Steam Injection : Introduces steam at high volumes and low velocity for uniform heat distribution.

Adjustable Mixing Blades : Wide, step-adjustable paddles ensure thorough mixing and consistent conditioning.

Hinged Inspection Covers : Unique design allows for quick, easy, and safe adjustments to paddles and settings

Maintaining precise accuracy over the conditioning by controlling moisture temperature & residence time, improve results of further operation like palletisation or expelling with minimal losses.

The use of VFD for main drive motor ensures precise initial torque control during their operation.

Safety guards with limit switches mitigate accident risks from rotating parts by triggering an instant shutdown if opened.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.