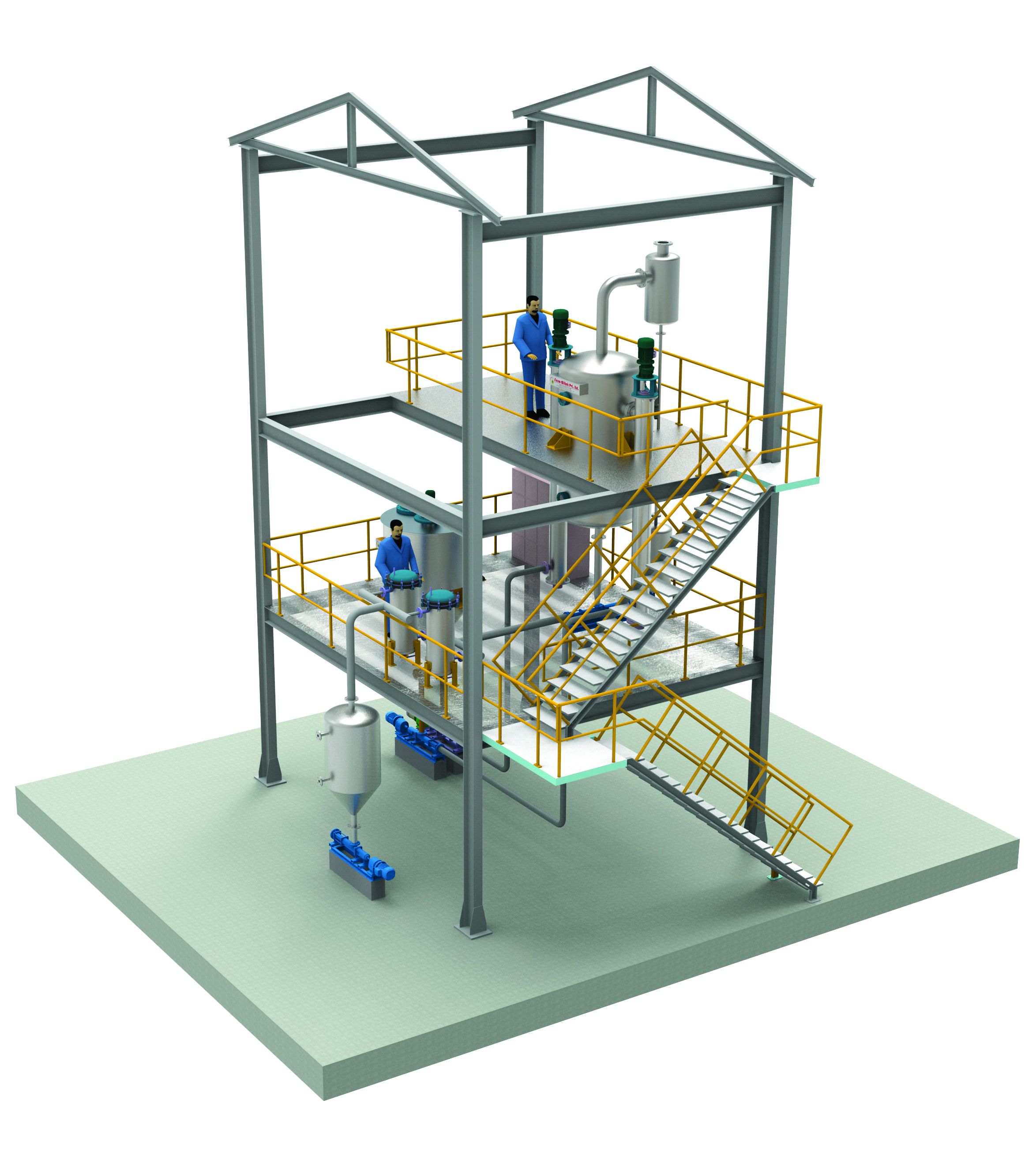

FX-Lecithin Drying Plant

Hydrated gums from the water degumming process are carefully homogenized before being fed into a specially designed scraped-surface thin-film evaporator. In this evaporator, moisture is efficiently removed, transforming the gum into dry lecithin. The feedstock’s residual moisture content is reduced to just 0.5% from an initial 50%, ensuring high-quality lecithin production.

- FERRO Offers Skid-Mounted & Customizable Lecithin Plant

- Precise Feed Control

Key Features

Robust Design: Built with a durable scraped-surface thin-film evaporator, requiring minimal maintenance.

Sealed Process Plant : Operates under low absolute pressure, ensuring optimal efficiency and safety.

Premium Material Construction : All product-contact parts are made of SS 304/ SS 316 for enhanced durability & hygiene.

Automated Control : PLC/SCADA-based automation options for streamlined operation and monitoring.

Superior Lecithin Quality : The final product is light in colour, with the lowest moisture content, free from microbial growth, and of the highest commercial market value.

Efficient Heat Transfer Mechanism:

Maximizes thermal efficiency using indirect heating.

Continuous Scraping Action : Rotating blades continuously remove the lecithin layer from the heat transfer surface, preventing build-up and ensuring consistent heat exchange.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.