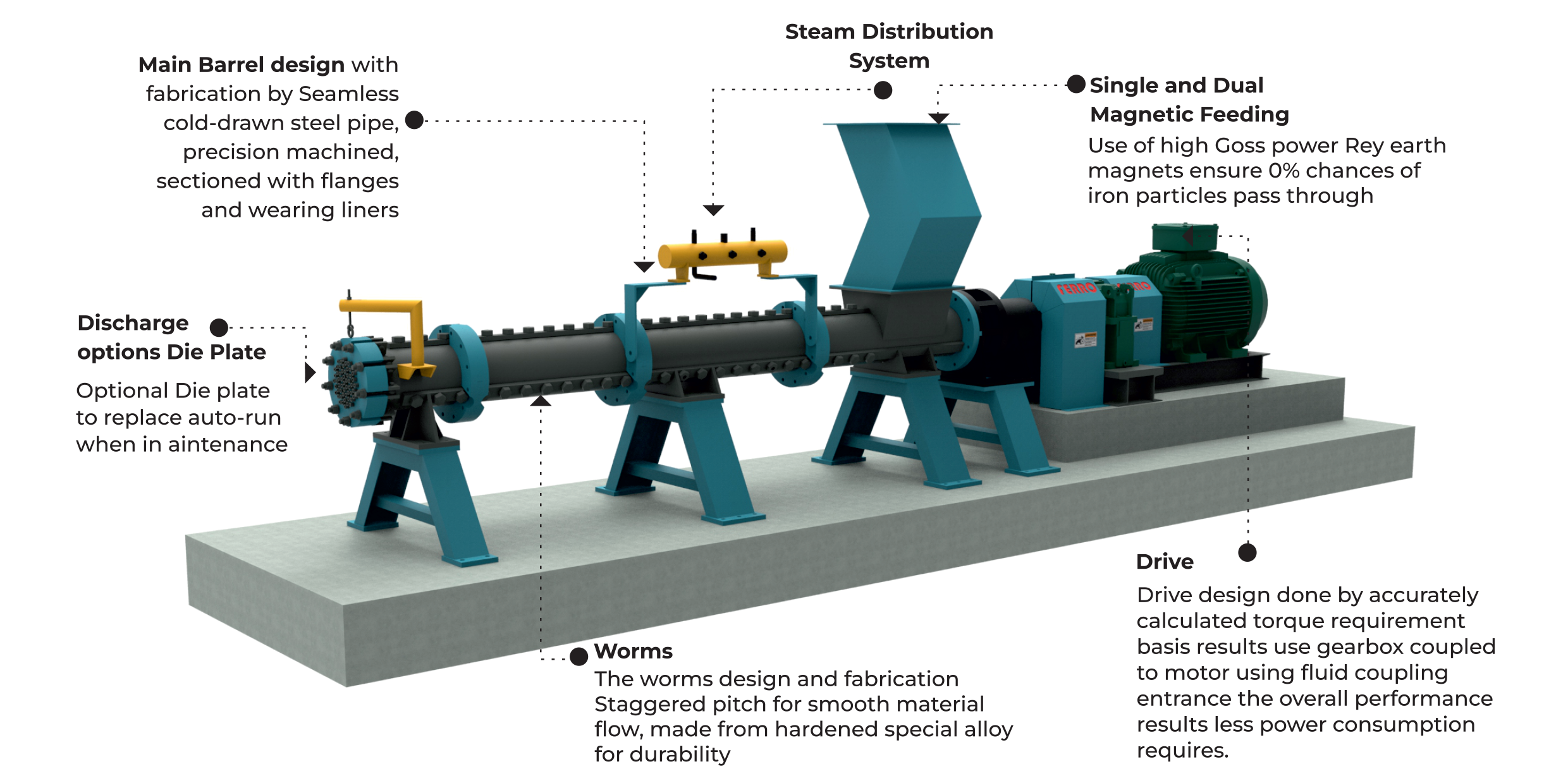

FX- OEX : Oilseed Expander

The use of FX-Expander Increases solvent plant capacity by up to 50%, reduces solvent hold-up in solid products by 40%, and lowers solvent carry-over in liquid products by 20% and due to better structural integrity of pallets or collets entering Desolventiser operation.

Advanced Design for Optimized Solvent Extraction & Desolventising :

The reengineered design concept over rotating warm hardened wear liners, sharing bolts & compression rings etc. performance producing output heavy dense pallets with having best porous structure area which result in enhancing solvent extraction & desolventising operation.

| Technical Specification | ||||

| Model | Capacity Per Day | Power Consumption (kW) | ||

|---|---|---|---|---|

| Soyabean | Sunflower/Rapeseed | Cottonseed | ||

| FX-OEX200 | 200 | 120 | 100 | 75 |

| FX-OEX250 | 500 | 320 | 200 | 112 |

| FX-OEX275 | 750 | 440 | 250 | 130 |

| FX-OEX300 | 1100 | 700 | 350 | 250 |

| FX-OEX350 | 1800 | 1300 | 450 | 400 |

Note : The mentioned capacity depends on the input seed parameters.

Key Features

High Pressure & High Shear Design concept processing oil seed efficiently

Instrumentation package provision accurately controlling the utility consumptions as per desire requirements.

Provision with adjustable orifice design concept accurately forming shape of pallets or collets.

The produces Pellets through FX-Expander provide a maximized surface area, Improving oil extraction efficiency from the meal.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.