Palm Oil Processing, Oil Extraction & Refining Plant

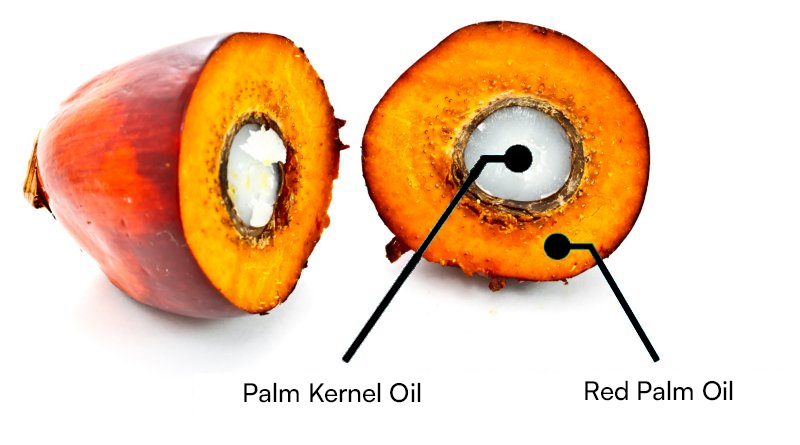

As we all know, Palm is an economic crop and oil palm is a kind of important tropic oil industry around the world. The oil content of the oil palm is very high, as follow, Palm fruit: 46%-50% and Palm kernel: 50%-55%. Here we mainly talk about the palm oil press production line, Palm oil pressing production line can be divided into two types of oil, A. Red Palm Oil B. Palm Kernel oil. Basically, the palm oil is processing line involved steps are, Palm fruit bunches reception, sterilization, threshing, digesting and pressing, oil clarification, and storage.

Here FERRO OILTEK delivers the solution over red palm oil production begins from, digesting and pressing, oil clarification, and storage. And Palm kernel basis palm oil process line begins from, Palm kernel cleaning, palm kernel Cracking & shell separating, FX-Palm Crusher, Cooking, Expelling and Filtration.

A. Red Palm Oil

Digesting and Mechanical Screw Pressing: Digesting can separate the pulp and nut and smash the pulp tissue, make it easy to press oil out. And then use double screw palm oil presser to press palm oil.

Crude Oil Clarification :

Crude palm oil undergoes FERRO's innovative Four-stage filtration process, ensuring zero sediment remains in the oil. The filtration steps involved are as follows:

1. FRT (Foots recovery Tank)

2. FX-Vibro Separator

3. FX-Plate and Frame Filter Press

4. FX-Polish filter (Fine filtration)

CPO Storage : The extra fine clarified crude oil is transported to the crude oil storage tank. Now the crude palm oil can be eaten directly or can be further refined into RBD palm oil.

B. Palm Kernel Oil

Cleaning: The cleaning process is essential for removing impurities, ensuring the quality of the final product, and protecting downstream equipment. We offer reliable cleaning solutions equipped with FX- Dry Destoner, FX-Box Type Seed Cleaner.

Plam Kernel Decortication : Before flaking or expelling operation, palm kernel must be properly cracked for optimal processing. Ferro's advanced FX-Decorticator machine is specifically designed to efficiently crack & separation of shell, ensuring smooth and effective preparation for the next stage.

Cooking : The cooker is used to heat and cook the crashed palm kernels, to make it suitable for pressing. Doing like this can help customer get the maximum oil and good quality cakes.

FX-Mechanical Screw Pressing : We offer both pre-pressing and full-pressing solutions tailored to meet our clients' oil yield requirements. Palm kernel oil pressing is similar with usual oilseeds. Only one difference is the oil expeller machine. The palm kernel oil expeller machine should be more wear-resisting.

Crude Oil Clarification :

Crude palm oil undergoes FERRO's innovative Four-stage filtration process, ensuring zero sediment remains in the oil. The filtration steps involved are as follows:

1. FRT (Foots recovery Tank)

2. FX-Vibro Separator

3. FX-Plate and Frame Filter Press

4. FX-Polish filter (Fine filtration)

Conventional Solvent extraction : Residual oil left in palm kernel cake/ palm fruit cake is forcefully extract by using solvent improves maximum oil yield production.

CPO Refinery : Vegetable oil refining machine is to refine the crude vegetable oil, getting rid of the deleterious impurities, then get the high-quality edible oil. According to the different capacities, the vegetable oil refining machine can be divided three types: batch type, semi-continuous type and fully continuous type vegetable oil refining machine.

Get your edible oil plant with our solutions

Interested in this technology for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.