FX-PBTSC:

Pneumatic Basket Type

Seed Cleaner

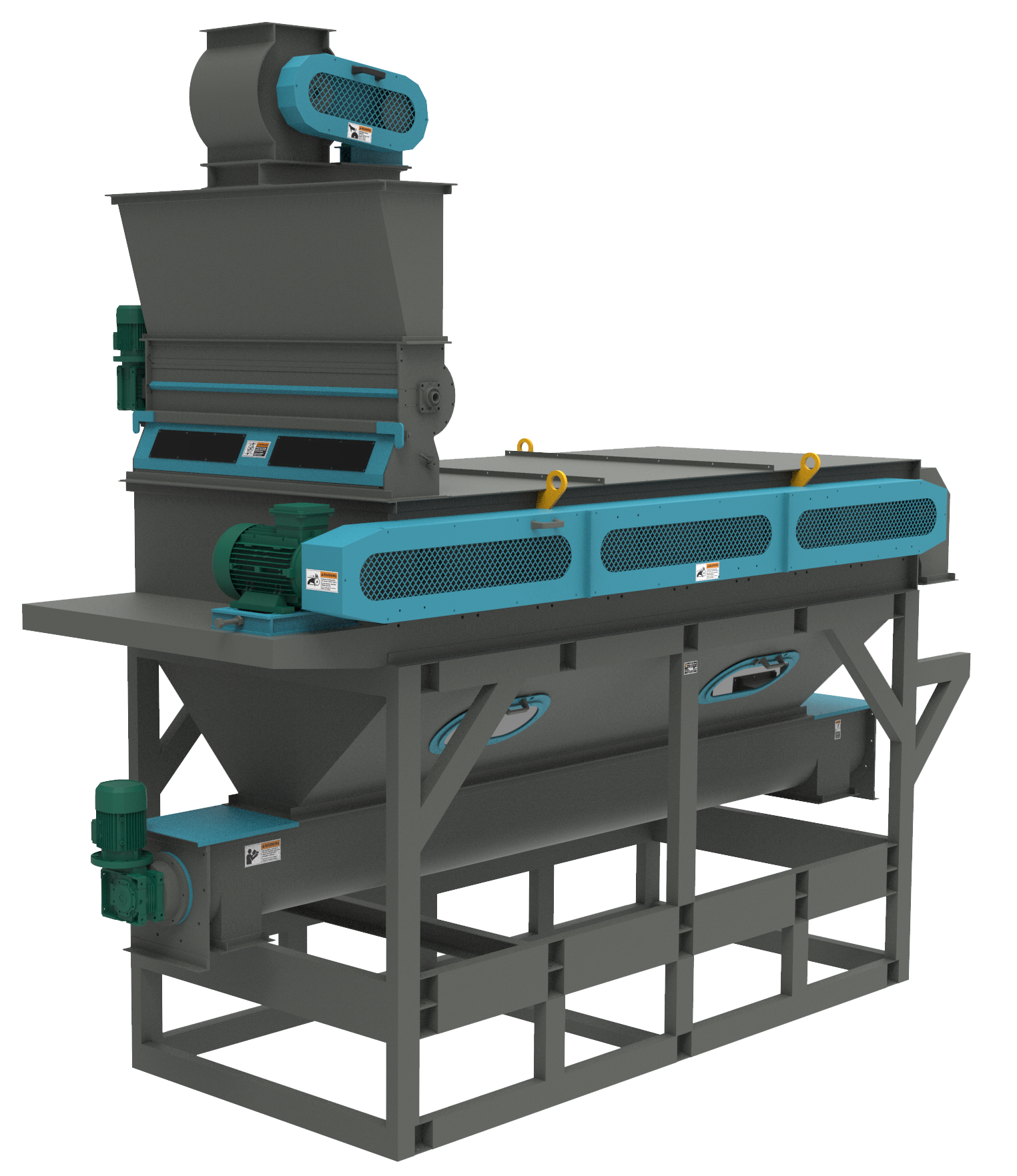

Pneumatic Closed Type Seed Cleaner is a uniquely designed machine with 8 stage basket beater which is used for getting maximum cleaning efficiency and minimizing the wear and tear for ease of removability & changeability. Cottonseed cleaner is the complete unit is designed to remove foreign material effectively and other all types of impurity from white cottonseed. We provide special stone separator & vacuum feeder for seed cleaning operation.

This machine used to produce clean seeds with higher cellulose, these cleaned seeds further obtained for De- linting & Dehulling operation. The Pneumatic Seed cleaner separates un-ginned cotton, stones, metal pieces, dust and fine impurities from seed at 99% cleaning off. Because of adroit seed cleaning other processing machines like Delinters & Hullers get protected. Due to higher cleaning efficiency the quality of bi-products (linters and DOC) gets improved.

Suitable For :

Removing all impurities from cotton seed at cleaning efficiency 99%.Operational Procedure:

The seed first enters to a special stone separator unit through a rotary feeder, as soon as seeds reside in the zigzag, the pneumatic suction will lift the seed. The vacuum is adjusted by control valve which lift the cotton seed and heavy impurities gets fall down (stones and metal). Then seeds move into the 8 nos basket beater, this basket beater having different sizes of sieves which helps to separate sticky dust, un-gin cotton and other bigger size impurities from cotton seed. After beating operation is done, the meshed down seed gets collected into the clean seed carry conveyor.| Technical Specification | |||

| Model | Capacity | Total HP | Dimensions (L x B x H) |

|---|---|---|---|

| FX-PBTSC-100 | 100 TPD | 33 HP | 5.1 x 1.7 x 4.6 mtr. |

| FX-PBTSC-150 | 150 TPD | 43 HP | 5.1 x 2.1 x 4.6 mtr. |

| FX-PBTSC-200 | 200 TPD | 50 HP | 6.1 x 2.1 x 4.6 mtr. |

Note : The mentioned capacity depends on the input seed parameters.

Key Features

The advanced 8-Stage beating technology enhances cotton seed cleaning by effectively removing contaminants beyond conventional methods.

The cleaner is equipped with a dedicated stone separator that accurately removes stones from cottonseed, even when the stone size is similar in size of cottonseed.

The cleaner machine outlet clean seeds result further processing equipment like delinter machine produces high cellulose content linters as a product.

The Seed Cleaner offers a high cleaning efficiency of up to 99%, ensuring that the cleaned seeds are free from contaminants such as un-ginned cotton, stones, metal, dust, and fine impurities.

By removing contaminants beforehand, these subsequent machines are less likely to experience damage or clogging from foreign materials (Specially Delinter and Decorticator machines).

Zero Speed Sensors ensure precise accidental monitoring for the compound drive system.

The precise feed rate control ensures optimal accuracy, enhancing the overall efficiency of subsequent operations.

The reengineered basket beater is precisely fabricated for easy maintenance and smooth opening and closing.

Safety guards with limit switches mitigate accident risks from rotating parts by triggering an instant shutdown if opened.

The use of VFD ensures precise initial torque control for the compound drive system of basket beaters

All bearings used in the rotating parts are from leading brands like SKF, NTN, FAG, etc., ensuring minimal power consumption.

Easy access door for inspection and maintenance.

Efficient cleaning improve the subsequent operational output by product (Linter & DOC) Quality.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.