Ferro's Pneumatic Conveying System

Pneumatic conveying systems use air as the transport medium. Pneumatic conveying is facilitated by combination of following products:

A. Galvanized Pipes:

We provide galvanized pipes ranging from 5" to 36" diameter with customized lengths, designed for durability and corrosion resistance. These pipes feature flanged ends with suitable filler material, ensuring leak-proof joints for secure and efficient installation across various applications.

B. Elbows or bends :

We manufacture GI elbows, bends, and transitions designed for pneumatic conveying systems, ensuring smooth airflow and minimal pressure loss. Engineered for high wear resistance and durability, these components facilitate seamless material transfer while reducing turbulence and abrasion. Available in custom angles and radii, they are precision-fabricated with flanged or plain ends for secure, leak-proof connections, ensuring efficient performance in bulk material handling applications.

C. G.I./M.S. diverters :

Diverter valves ensure precise redirection of material flow between different transport lines without cross-contamination.

Specifications:

Type: Two-way, Three-way, and Multiport Diverters

Material: GI, MS, SS304, SS316

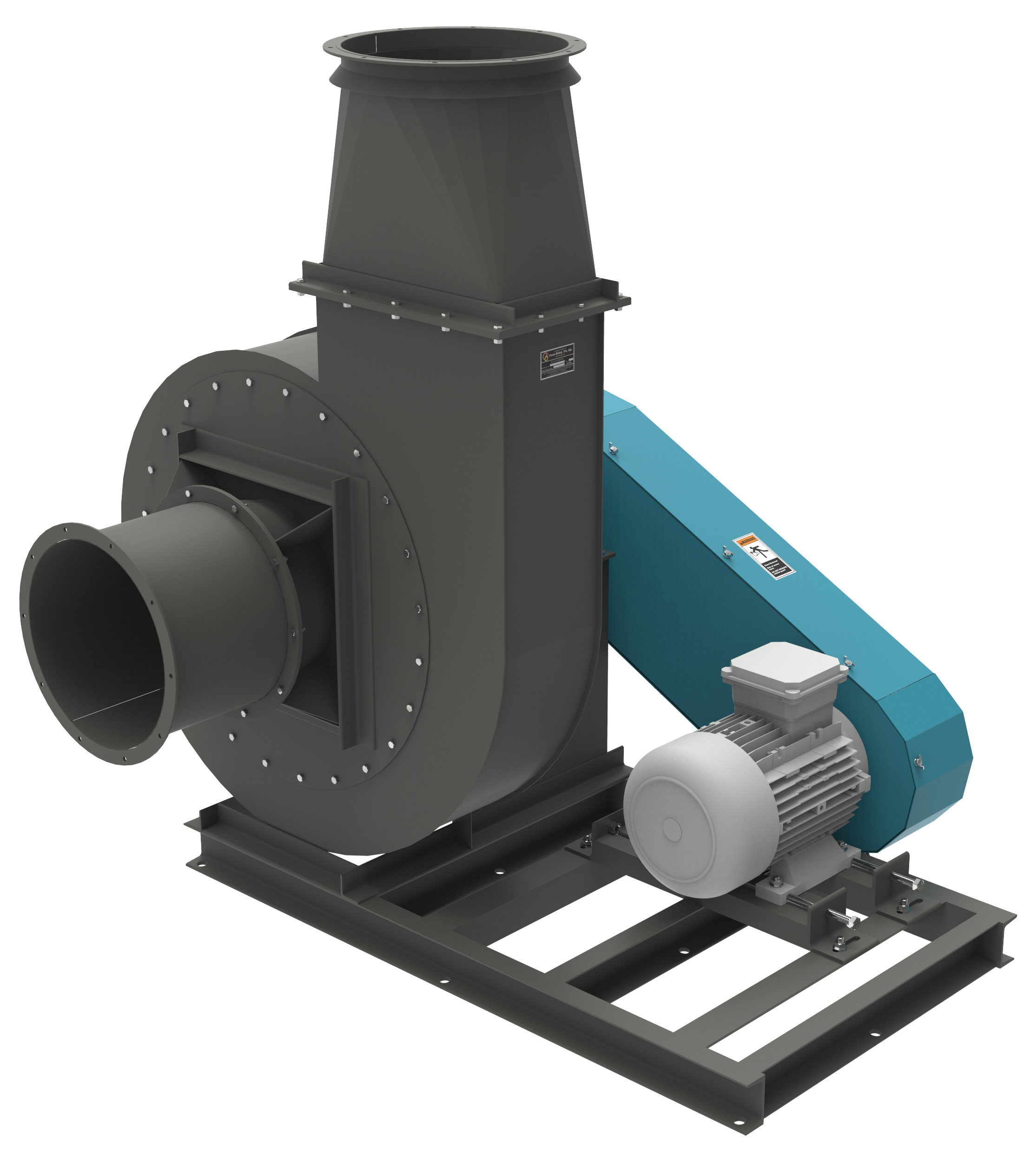

D. Centrifugal Fans :

These are used to create pressure differentials toinduce efficient airflow to carry the material. We have a wide range of Blowers which are dynamically balanced.

Type: Backward-curved, Forward-curved, Radial Blade, Paddle Wheel

Material: MS, SS304, SS316 etc

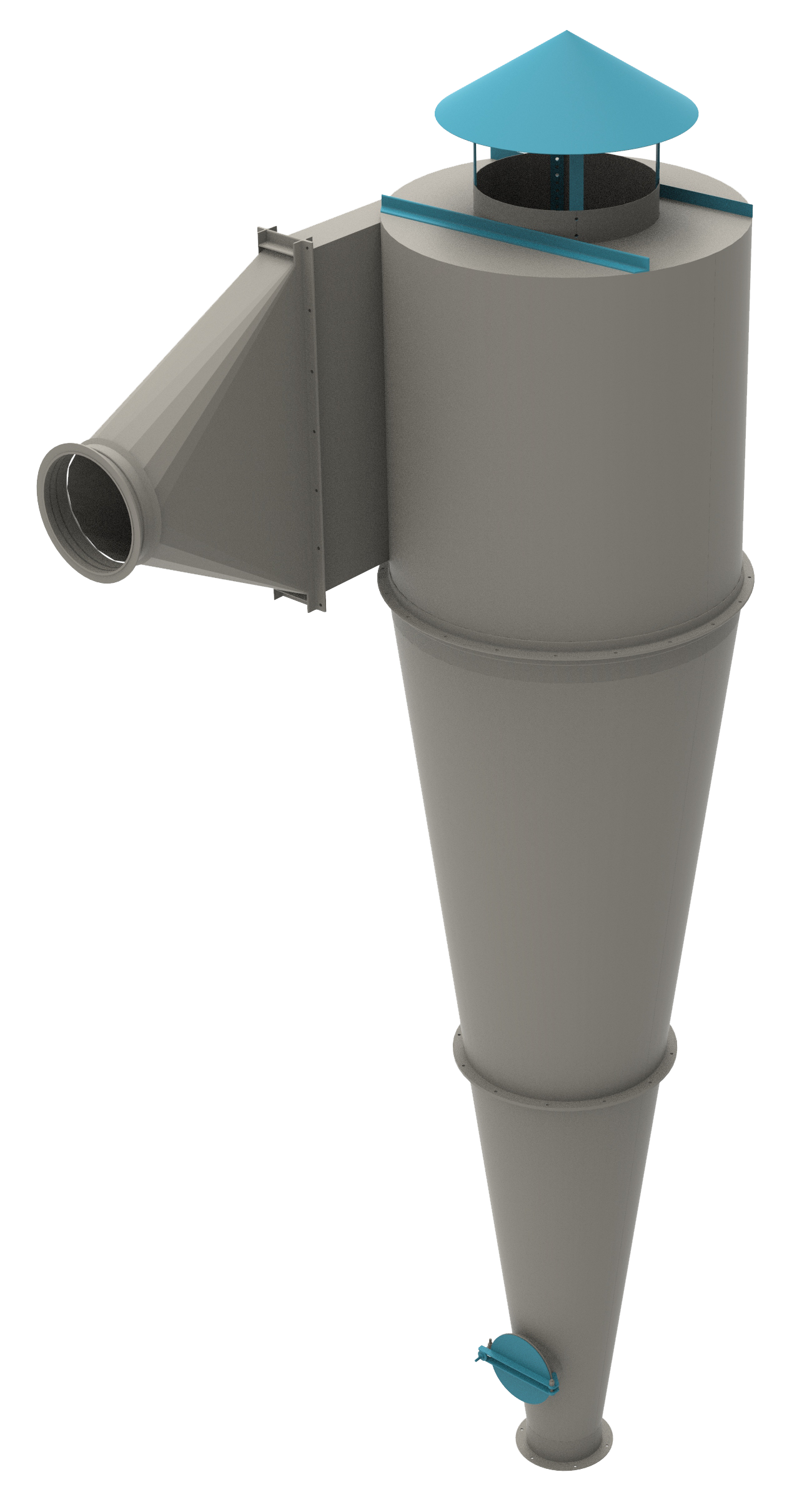

E. Cyclone

High-efficiency cyclones enable effective separation of particulates from the conveying air, ensuring cleaner air discharge and material recovery.

Specifications:- Material: MS, SS304, SS316, GI

- Diameter: 300 mm to 2000 mm

- Efficiency: 90-99% (depending on particle size)

- Pressure Drop: 50 – 250 mm WC

- Inlet Velocity: 10 – 25 m/s

- Collection Efficiency: 1-5 micron for fine dust, coarser separation for larger particles

- Separation of fine dust and bleaching earth from conveying air in oil refineries

- Recovery of valuable fine powders such as fly ash in power and cement plants

- Efficient removal of seed husks and fines in oilseed processing units

- Pre-filtration of air streams before passing through baghouse filters.

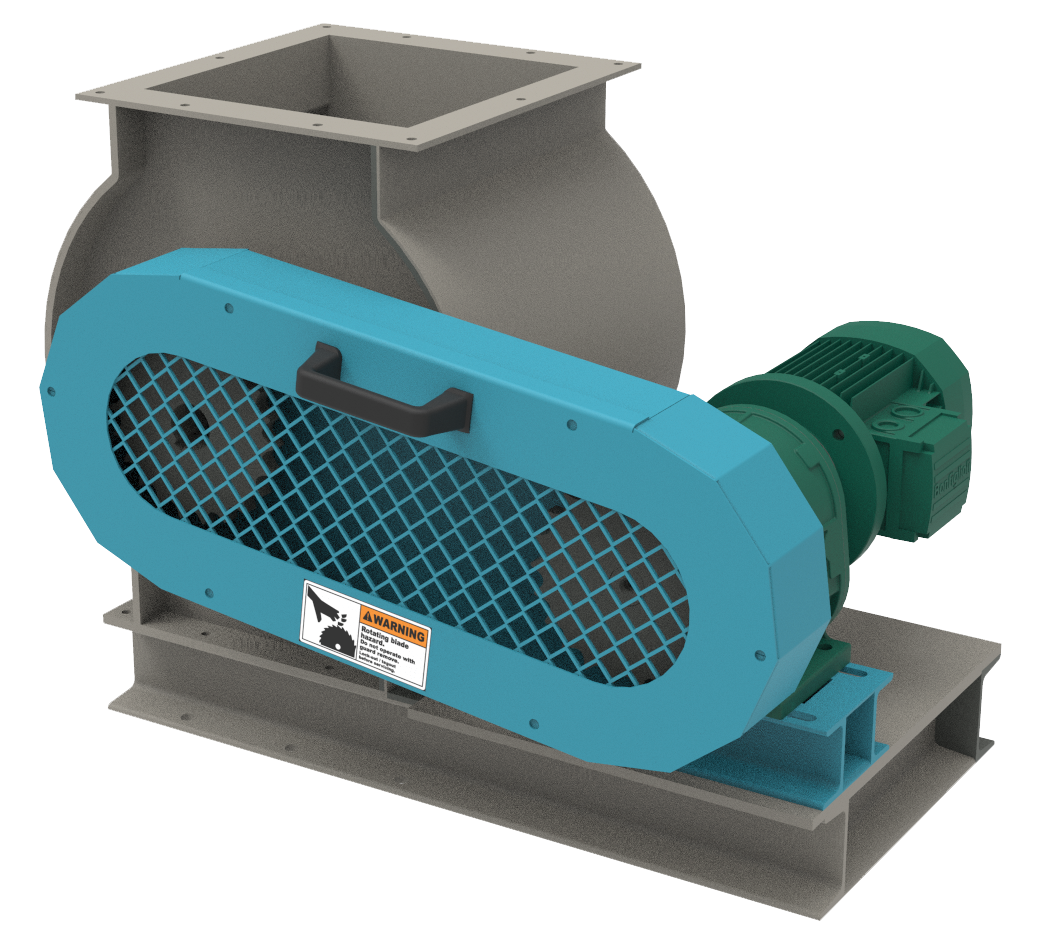

F. FX Air Lock :

- Prevents Air Leakage : Maintains pressure balance, preventing unwanted air infiltration or loss.

- Enhances Material Flow Control : Ensures consistent feeding of bulk materials without interruptions.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.