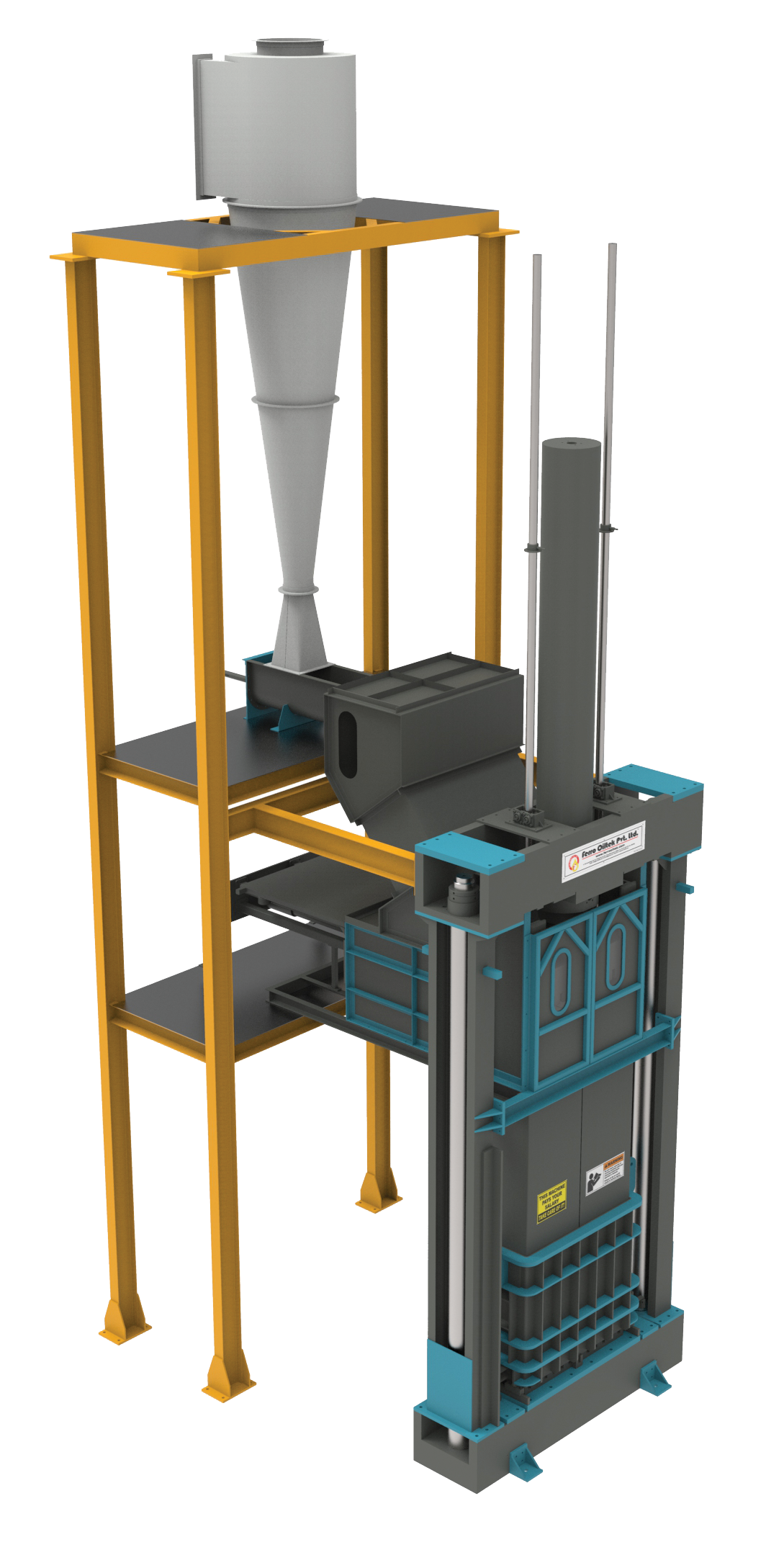

FX-SBBP :

Single Box Cotton Fibre

Bailing Press

The FX-Single Box Bale Press Machine is designed to efficiently compress ginned cotton and delinted linters, reducing volume and increasing density for improved handling, storage, and transportation efficiency.

Re-engineered design ensures easy operation, low power consumption, and minimal labour costs.

The twin pusher option boosts operational speed, making processes faster and more efficient.

Use of hydraulic components from renowned brands like Bosch Rexroth, Hydac etc for durability and reliability.

SAFETY FEATURES:

- Equipped with proximity sensors, limit switches, and check valves to prevent accidents and enhance safety.

- Equipped with guide rods to prevent turn around of main ram cylinder.

CUSTOMIZABLE OPTIONS:

- The Ferro Single Box Bale Press can be tailored to customer needs, including options for single or double pushers.

- The Ferro Single Box Bale press can be equipped with online bagging/ online weighing.

| Technical Specification | ||||||

| Model | Capacity | Motor HP | Dimensions (L x B x H) | Bale Weight | Panel Mode | Bale Density |

|---|---|---|---|---|---|---|

| 55" x 21" x 28" | 6-9 BPH | 37.5 HP | 2.9 x 5.3 x 8.5 mtr. | 220 KG | Fully Automatic | Universal / High |

| 48" x 18" x 18" | 6-9 BPH | 37.5 HP | 2.9 x 5.3 x 8.2 mtr. | 180 KG | Fully Automatic | Universal / High |

Note : Sizes without powerpack / cyclone / structure

Key Features

Robust Construction : The machine's durable body structure ensures zero vibration, promoting stability during operation..

Advanced PU Coat Finish : Provides an easy-to-clean surface, long-lasting appeal, and excellent aesthetics.

Space-saving design that makes the machine efficient and easy to operate.

User-Friendly HMI PLC System : Built to deliver high-speed operation, enhancing productivity.

Redesigned Lint Box & Pusher Rollers : All critical components undergo precision machining exclusively in FERRO's in-house CNC facility, ensuring the highest standards of accuracy for seamless part matching during assembly.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.