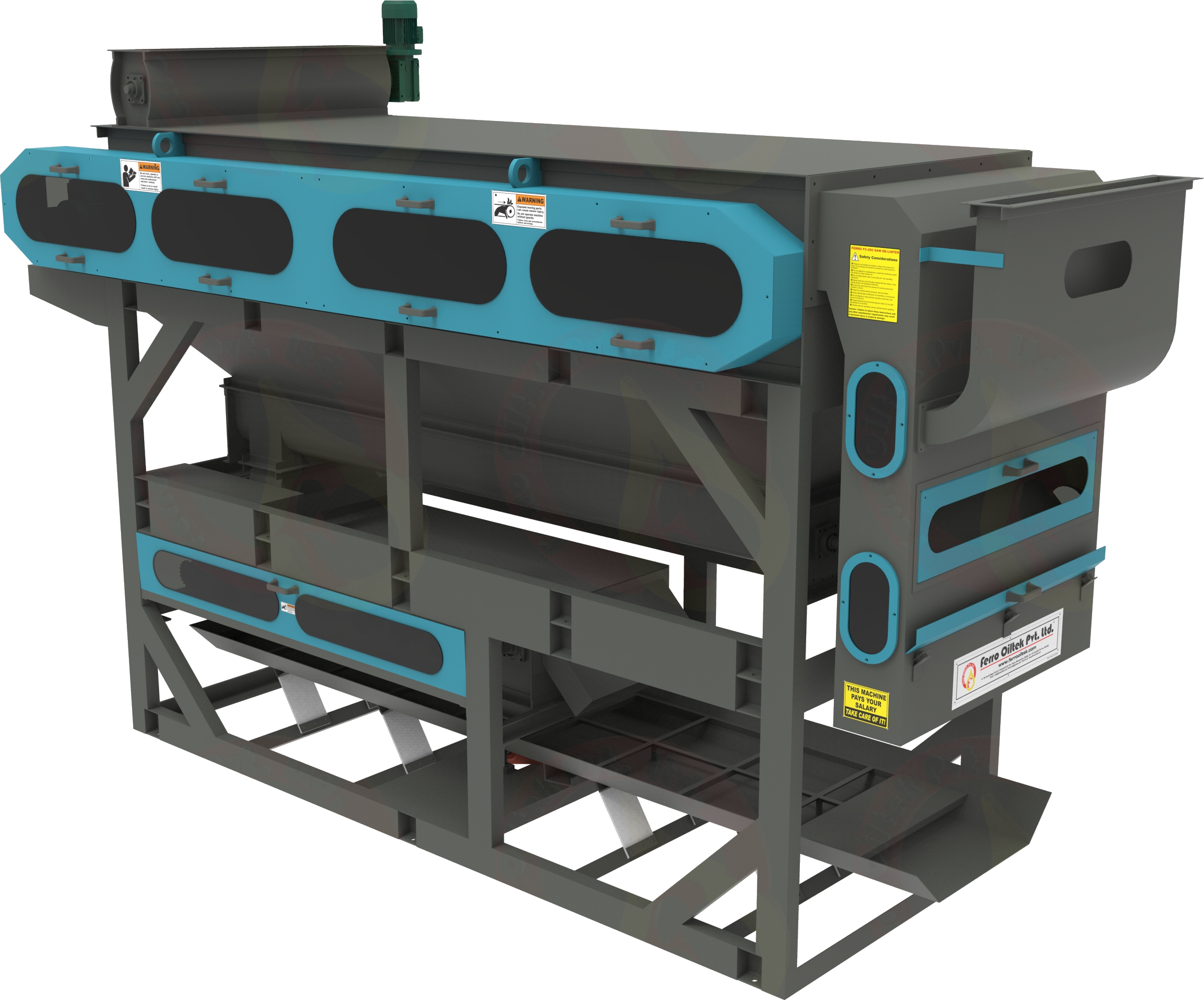

FX-SSLC :

Seven Stages Lint Cleaner

The advanced lint beating technology enhances cleaning efficiency by effectively removing contaminants (dust, hulls, meat particles & other trashes etc.) beyond conventional methods to ensuring superior lint quality. This lint cleaner provides highest capacity & good quality of lint according to today's market need. Dirty linter recycling system for higher yield of cotton linter.

| Technical Specification | |||

| Model | Capacity | Motor HP | Dimensions (L x B x H) |

|---|---|---|---|

| FX-SSLC-8 | 8 TPD | 15 HP | 5 x 1.8 x 3.3 mtr. |

| FX-SSLC-10 | 10 TPD | 18.5 HP | 5 x 1.8 x 3.3 mtr. |

Note : The mentioned capacity depends on the input seed parameters.

Key Features

The precise feed rate control ensures optimal accuracy, enhancing the overall efficiency of subsequent operations.

The reengineered basket beater is precisely fabricated for easy maintenance and smooth opening and closing.

Safety guards with limit switches mitigate accident risks from rotating parts by triggering an instant shutdown if opened.

Optimized for higher yield of cotton linter makes provision of producing dirty lint recycling.

All bearings used in the rotating parts are from leading brands like SKF, NTN, FAG, etc., ensuring minimal power consumption.

Zero Speed Sensors ensure precise accidental monitoring for the compound drive system.

The use of VFD ensures precise initial torque control for the compound drive system of basket beaters

Designed with a heavy-duty fabricated machine body frame to ensure minimum vibration.

Easy-access glass windows for inspection and maintenance.

Providing Inspection windows for clear internal separation visibility.

Conveniently Positioned Motors: Electrical motors are strategically located for easy access and quick maintenance

Producing Maximized Linter Cellulose Yield

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.