At Ferro Thermtek, we recognize that every mixing process has its own unique set of requirements. That’s why our agitators are engineered for flexibility and customization, making them ideal for a wide range of applications—from blending chemicals to handling high-viscosity substances. Industries rely on Ferro Thermtek’s agitators for their tailored configurations, including top-entry, side-entry, and bottom-entry designs, which cater to specific process needs. Constructed from robust materials like stainless steel and Hastelloy, our agitators are built to endure even the most demanding industrial environments. Moreover, their advanced impeller designs enhance energy efficiency and mixing performance, helping reduce energy consumption and lower overall operational costs.

Reactor Agitator

Designed for chemical reactors, this agitator ensures uniform mixing of reactants, proper heat distribution, and controlled reaction kinetics. It is built to withstand pressure, temperature, and corrosive environments.

Turbine Agitator

Ideal for mixing low to medium viscosity fluids. It features multiple flat or curved blades that create high shear and axial flow, suitable for emulsification, dispersion, and gas-liquid mixing.

Helical Agitator

Used for mixing high-viscosity materials like pastes, gels, and polymers. The helical ribbon or screw design allows smooth, gentle mixing and efficient movement of materials from top to bottom.

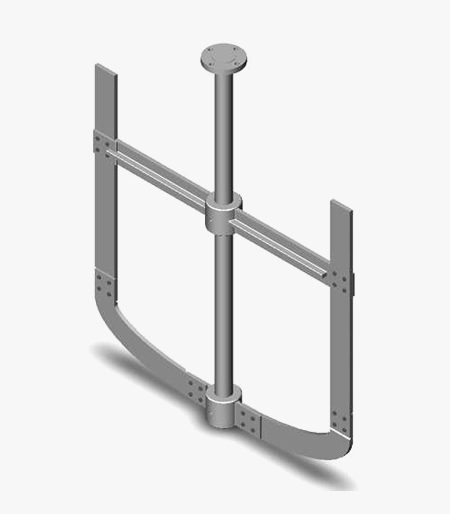

Anchor Agitator

Slow-speed designed for highly viscous products. Its sweeping motion scrapes the vessel walls ensuring complete mixing & heat transfer.

Paddle Agitator

Suited for uniform mixing of liquids and light pastes. The flat blades provide low-shear mixing, making it ideal for heat-sensitive or delicate materials.

Propeller Agitator

Best for low-viscosity liquids. The high-speed rotating blades generate axial flow, which is ideal for blending, solids suspension, and fast mixing operations.