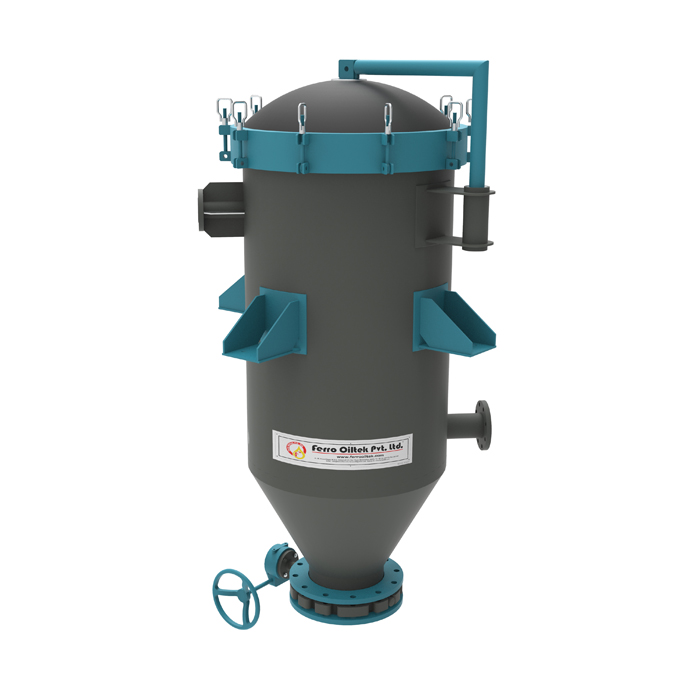

VPLF (VERTICAL PRESSURE LEAF FILTER)

- Home

- VPLF (VERTICAL PRESSURE LEAF FILTER)

- Edible Oil Industries

- Agro Chemicals

- Bulk Drug Intermediate

- Food Industry

- Speciality Chemicals and fine Chemicals Industry

- Resin & Paint Industry

Ferro's Pressure Leaf Filter is a result of advanced and proven technology. This Vertical Pressure Leaf Filter is widely used across various industries globally. In contrast, many Indian industries still rely on the outdated plate and frame type filters, which are bulky, require frequent filter cloth replacement, demand high manual effort, cause significant product losses, and create an untidy working environment.

The Pressure Leaf Filter offers a far more efficient, cost-effective, and cleaner solution. It operates without the need for filter cloth or excessive manpower and, being a closed system, ensures a clean and organized process area.

Ferro’s Leaf Filter consists of a vertical vessel housing multiple filter leaves mounted vertically on a central manifold that carries the filtered liquid. Each filter leaf features stainless steel wire mesh on both sides, supported by an SS channel around the edges, providing a large filtration area within a compact unit. To aid in easy discharge of the filter cake, the system includes large bottom outlet valves and is equipped with a pneumatic vibrator for efficient operation.

- Filter Cloth not required

- Saving in Labour Charges

- No Moving Parts

- Very Low maintenance cost

- No loss of liquid in filter cloth

- Easy in Operation

- Simple & Sturdy Construction

- Complete enclosed system

- Saving in space requirement & structural cost

- No mess in cake discharge

- No wastage of steam in cake drying operation

- Totally indigenous