Rice Bran Oil Extraction Technology

Rice Bran Oil has gained immense popularity in recent years as one of the healthiest and most versatile cooking oils. Praised for its neutral taste, high stability at high temperatures, and suitability for frying, BBQs, salad dressings, and baking, it is often considered a top choice for those seeking a healthier oil. Compared to other vegetable oils, Rice Bran Oil contains higher levels of plant sterols (phytosterols) and Gamma-Oryzanol, both known for their ability to reduce LDL cholesterol. This has led to a rise in interest and investment in rice bran oil processing. The advanced expansion technology used in processing increases extraction efficiency, reduces residual oil, and improves the quality of the oil. With the negative pressure evaporating system, the oil retains its good quality and light color while minimizing steam consumption. Additionally, the adoption of a mineral oil system helps reduce solvent usage, making the process both efficient and environmentally friendly.

Check Process Flow Video ->Initial Cleaning and Separation of Rice Bran

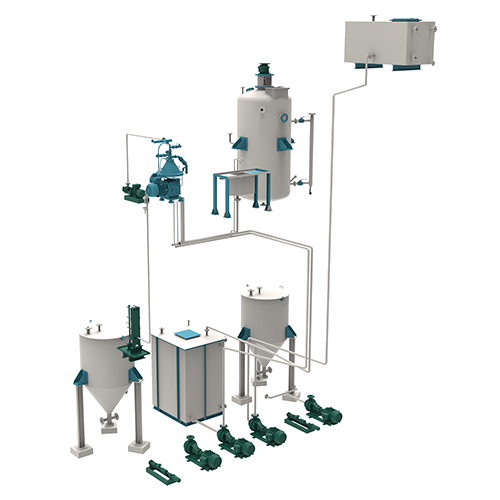

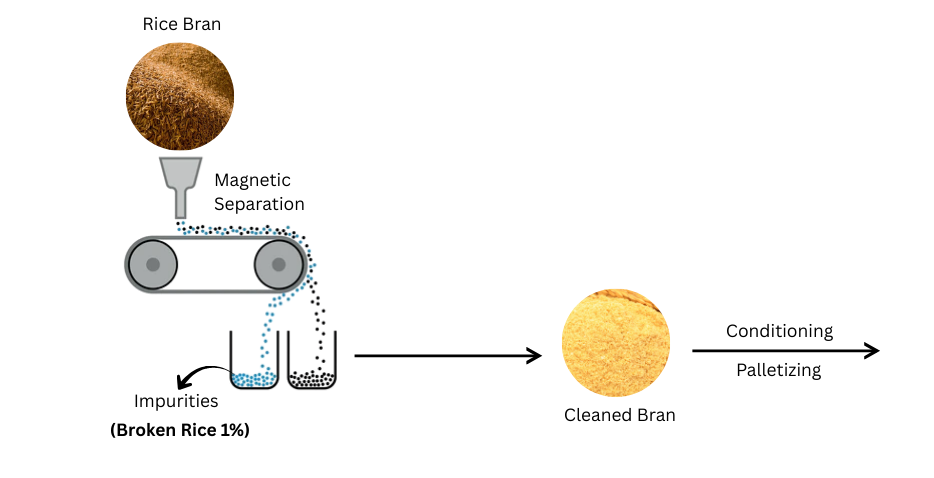

The process of preparing rice bran for oil extraction involves a two-step cleaning and separation process:

1. Magnetic Separation: The raw rice bran first goes through a magnetic separator. This machine removes iron contaminants, such as metal fragments, that may have mixed with the bran. This step is essential to protect the machinery from damage and ensures a smoother, more efficient expansion process later on.

2. Separation from Broken Rice: After the magnetic cleaning, the rice bran is separated from any broken rice kernels. This separation is done to ensure smooth operation of the extraction machinery, reduce the use of solvents, and ultimately increase the overall oil yield. By removing the broken rice, which contains less oil, the process becomes more efficient, and the final product has a lower residual oil content.

Related Products :

Plant Images :

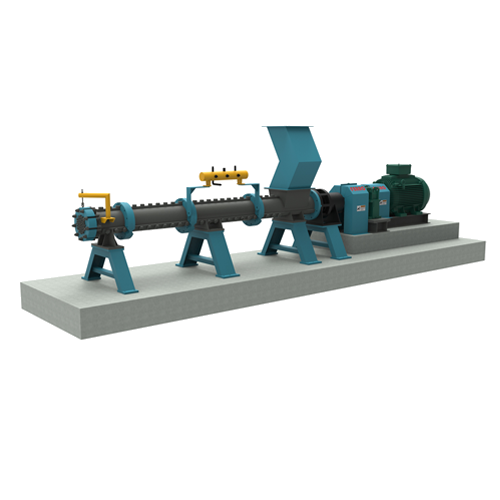

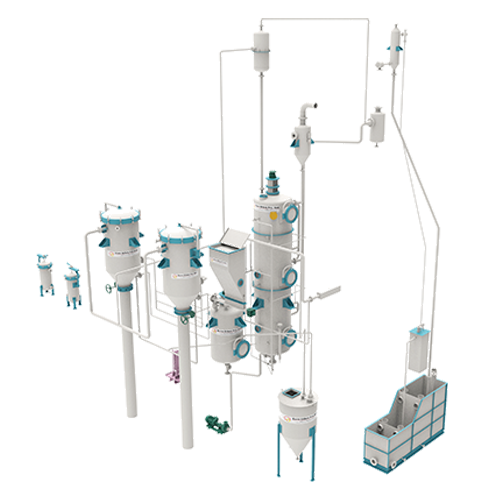

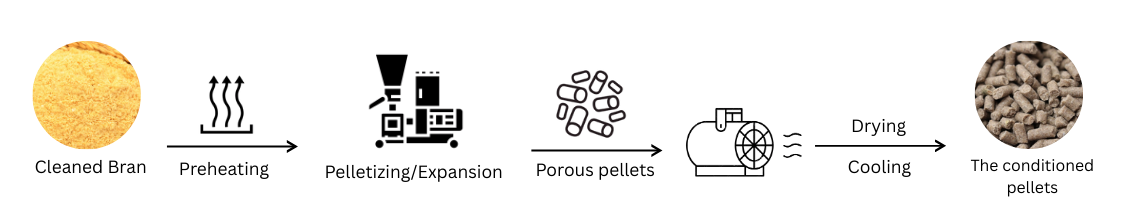

Rice Bran Conditioning, Palletizing

The conditioning process plays a crucial role in preparing rice bran for efficient oil extraction. In this stage, the rice bran is carefully preheated to a controlled temperature in order to adjust and optimize its moisture content. This step ensures that the bran achieves the right balance of heat and humidity, which is essential for improving the expansion properties during subsequent processing.

Once the desired temperature and moisture levels are achieved, the conditioned rice bran is passed through pelletizing or expanding equipment, where steam is applied under pressure. The combination of heat, pressure, and moisture causes the bran particles to expand, resulting in porous, sponge-like pellets. These porous pellets enhance the surface area of the bran, thereby improving solvent penetration and oil recovery efficiency during the extraction phase. After expansion, the hot and moist pellets are transferred to a pneumatic drying and cooling system, where they are rapidly dried and cooled to stabilize the material and prevent degradation of nutrients or oil quality. This drying process not only reduces moisture to the desired level but also makes the expanded bran more durable and easier to handle in the downstream extraction process.

Plant Images :

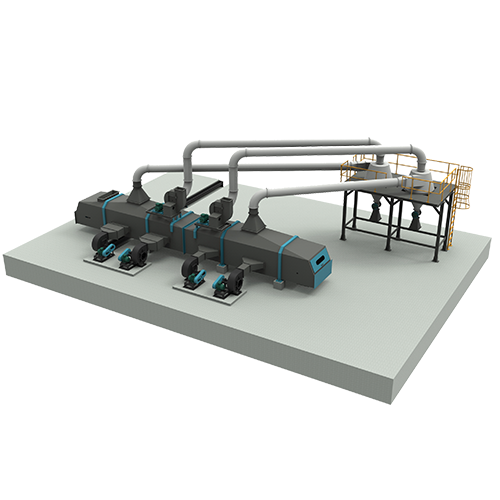

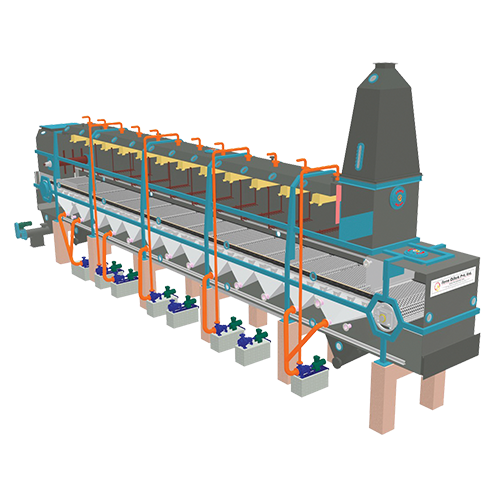

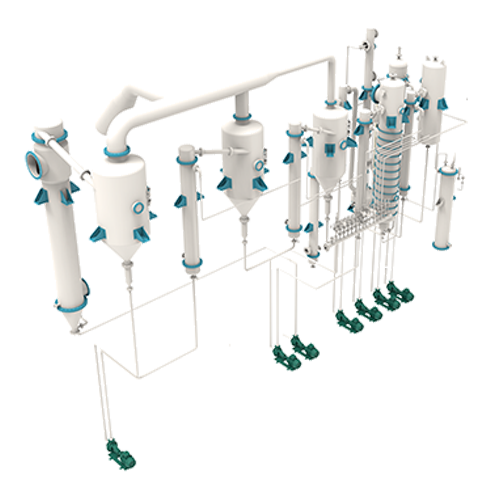

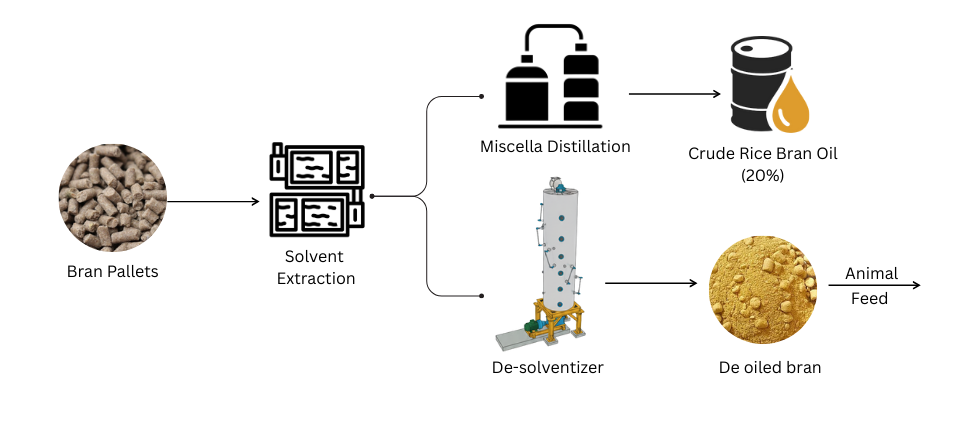

Solvent Extraction

The expanded rice bran pallets enter into the Ferro LM solvent extraction is a method used to extract the oil from rice bran pallets with using a solvent (typically hexane), further drained wet meal is sent to the DeSolventiser for producing solvent free DORB meal and followed by produces miscella (hexane+oil) is further process into FX-Miscella Distillation to recover hexane by making process efficient with achieving best results of minimal hexane losses.

Plant Images :

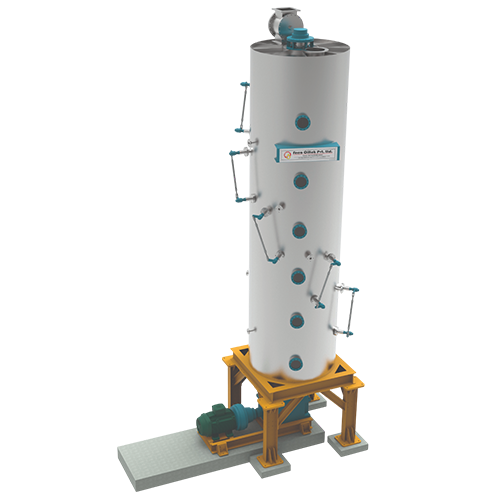

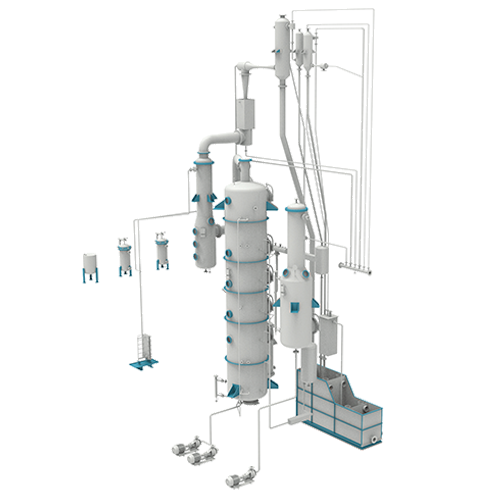

Rice Bran Refinery

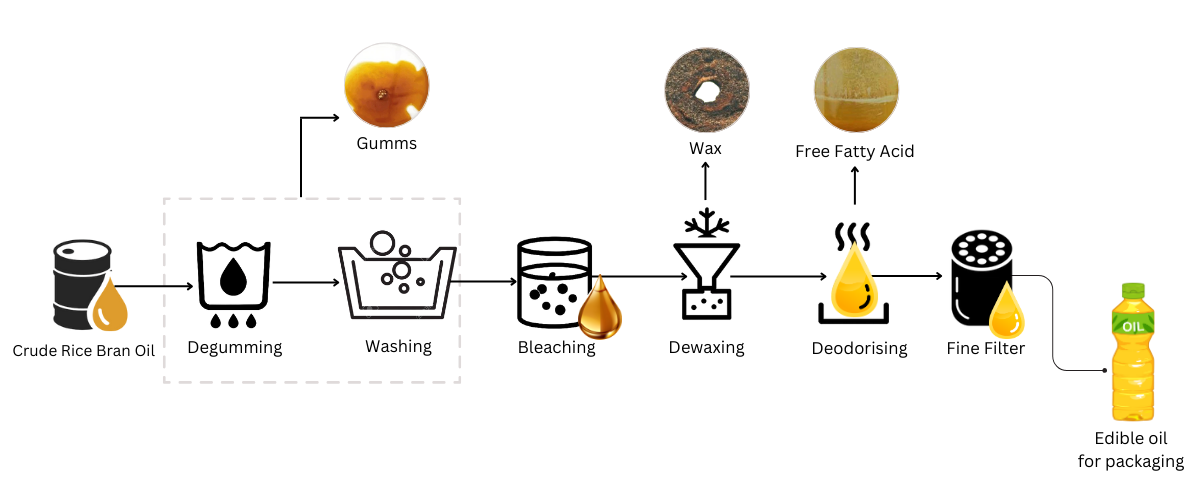

The Rice bran Edible Oil Refining Process involves several stages to transform crude rice bran oil into a high-quality edible oil. Rice bran oil is typically refined through physical methods to retain its beneficial Gamma-Oryzanol content. The physical refining steps include:

- Hot Water Degumming & Washing (remove phospholipid)

- Bleaching (remove colour pigments by treating oil with activated carbon or clay)

- Dewaxing (remove waxes by oil is chilled and then filtered the solidified wax & fats)

- Physical Deodorization (eliminates undesirable odors & volatile compound by oil heated under a vacuum)

- Winterization (Optional)

Finally refined oil is further undergone through FERRO new design FX-Ultra Fine Polish filter to making ultra-pure polished edible rice bran oil for cooking.

Plant Images :

Process Flow

Expert Answers for Smart Decisions

Get your edible oil plant with our solutions

Interested in this technology for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.