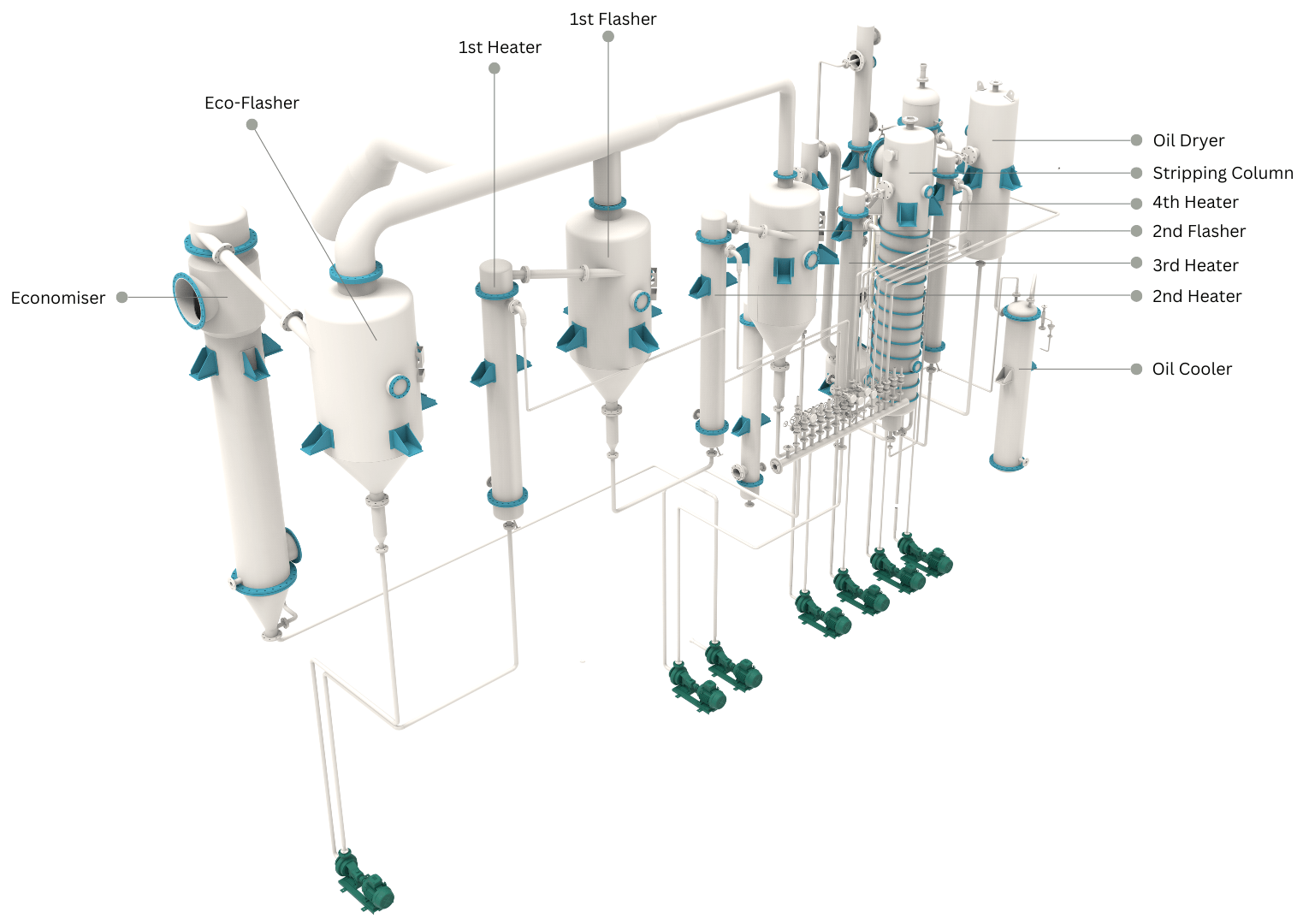

FX-Miscella Distillation

Efficient Miscella Separation :

FX-Distillation equipment’s include distillation & Evaporator equipment, heat exchanger and other special equipment’s are precisely designed using mass balance calculations and heat transfer coefficients to efficiently separate thermally, yielding pure oil and solvent vapor.

- Easy-access manhole & hand hole for inspection and maintenance

- Providing Inspection windows for clear internal separation visibility.

- Robust Construction – Fabricated from corrosion-resistant stainless steel or carbon steel with protective coatings, ensuring durability and longevity.

- Optimized Stripping Column Geometry – Engineered with an optimal height-to-diameter ratio and structured internals (such as trays or packing) to enhance mass transfer, maximize contact area, and improve stripping efficiency.

- High-temperature gaskets, precision-cut via water jet, ensure accurate profiles and eliminate leakage.

Key Features

Energy-Efficient Operation : utilisation of low steam consumption results reducing operational costs.

Precision automated steam control valves ensure a hexane is effectively vaporized without overheating the oil and improving the process efficiency.

Incorporates advanced recovery systems for enhanced sustainability.

Reengineered Hydro-Clones design enhanced hexane vapor separation.

Specialized Stripper & Dryer : Effectively removes solvent and moisture, ensuring superior oil quality.

Eco-Friendly Operation : Minimizes effluent generation, promoting a more sustainable process.

Self-Cleaning Design tubes Allows minimal sludge deposition to result maintaining constant heat transfer coefficient which improves overall efficiency of plant and minimum downtime.

Optimized Condensation System : Specially designed condensers ensure efficient solvent recovery at reduced vacuum across varying cooling water temperatures.

Advanced Vapor Absorption & Stripping: Captures uncondensed hexane from vent gases, preventing solvent loss and environmental impact.

Advantages of Ferro’s Advanced Stripping & Evaporation Design

Lower Residual Solvent in Oil

Achieved through maximized steam/oil contact, ensuring superior oil purity.

Innovative Sieve-Tray Stripper

More efficient than conventional disc/donut designs, enhancing solvent removal.

Energy-Saving Miscella Heating

Requires 15°C lower miscella temperature, reducing second-stage evaporator steam consumption and preserving oil quality.

High-Efficiency 2-Pass Evaporator

Ensures fast miscella tube velocity, significantly reducing tube fouling and cleaning frequency.

Minimal Oil Degradation

Lower heating requirements prevent crude oil deterioration before refining.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.