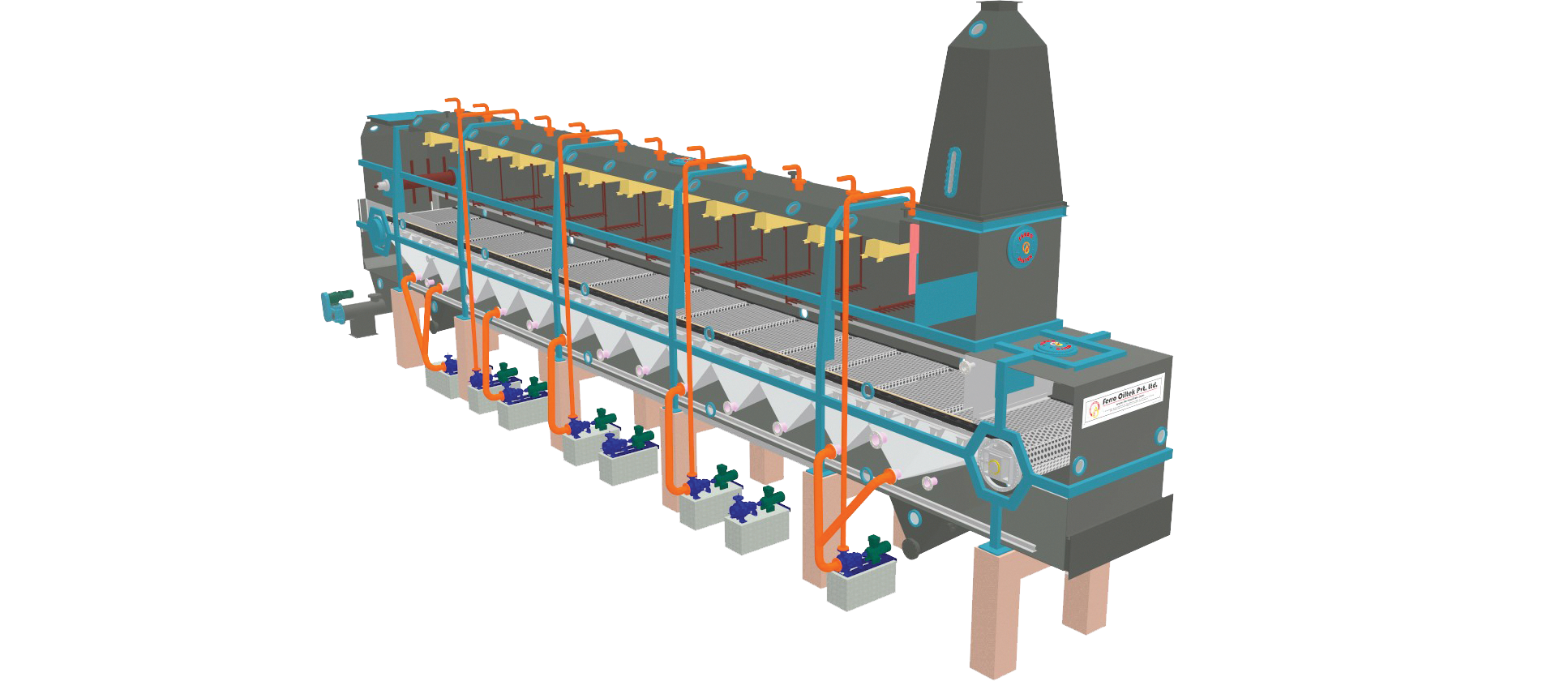

FX-Extractor

The FX-Extractor is engineered for maximum efficiency and durability, incorporating a new and improved design that enhances performance across all applications. Its long percolation sequence ensures thorough extraction, delivering optimal results every time. Built with strong, high-quality construction, the FX-Extractor is made to withstand demanding industrial conditions, providing long-lasting reliability.

Designed with easy installation in mind, it allows for quick setup and minimal maintenance, saving time and reducing operational hassle. Additionally, exterior access simplifies monitoring and servicing, ensuring smooth operation without disruption. Whether for industrial plants, edible oil refineries, chemical industries, or energy sectors, the FX-Extractor sets a new standard for efficiency and performance.

Key Features

Feed Hopper Feature : Input feed immediately saturated with miscella for rapid extraction & equipped with minimum and maximum level controls to ensure a consistent material feed and prevent mass balance of solvent use.

Optimized Miscella Contact & Oil Recovery : The FX-Extractor’s immersion sequence surrounds the oilseed material with miscella, ensuring deep penetration for efficient oil recovery. A segmented bed chain conveyor made of wedge bar or mesh screens supports the material, optimizing extraction flow.

Uniform Material Discharge & Cleaning : The level-controlled feed hopper regulates chain speed, maintaining a consistent material bed. Rakes ensure even distribution, and a rotary drum shaft acts as a lump breaker for smooth meal discharge.

Self-Cleaning & Low Maintenance : Dual high-pressure hexane sprayers remove residual material from the belt, reducing fouling. A mechanical scraper prevents material buildup and enhances operational efficiency.

Rakes for Percolation : Rakes on the material bed surface, along with a belt system, maintain percolation and prevent miscella contamination.

Advanced Planetary Gearbox : The extractor's main drive utilizes a newly designed planetary gearbox, which enhances efficiency and optimizes space utilization and 0% of down time.

Long-Lasting Conveyor Chain : Features a special, long-life conveyor chain for durable, consistent operation.

Auto Control & Uniform Discharge : Equipped with auto control for smooth operation and uniform discharge, ensuring consistent output.

Increased Miscella Contact Time : Compared to shallow bed designs, this system provides longer contact time for deeper miscella penetration, allowing thicker flakes to achieve the desired residual oil content.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.