Soybean Seed Processing, Oil Extraction & Refining

Ferro’s SoybeanSeed Processing ensures high-quality oil with minimal processing, retaining the natural flavor and nutritional benefits. Here’s an overview of the process:

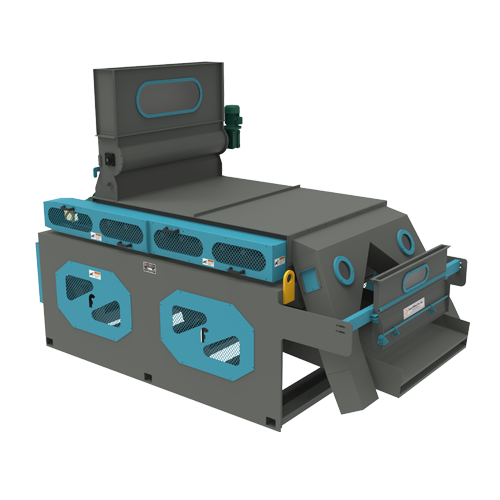

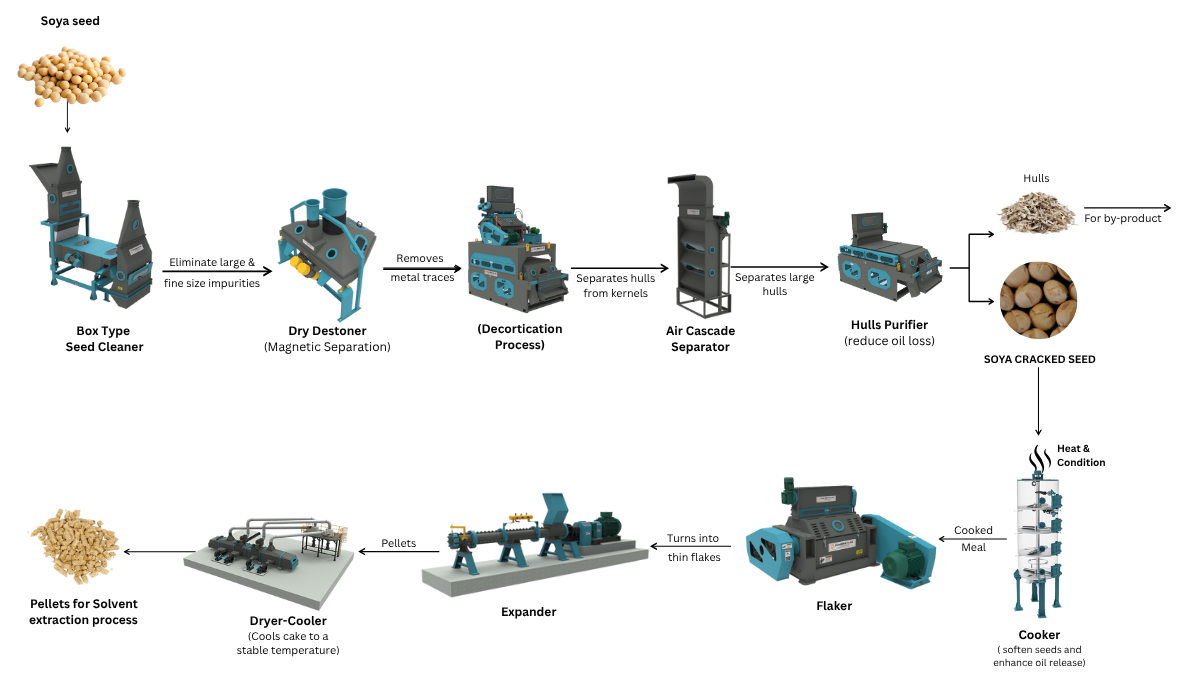

Seed Cleaning and Dehulling

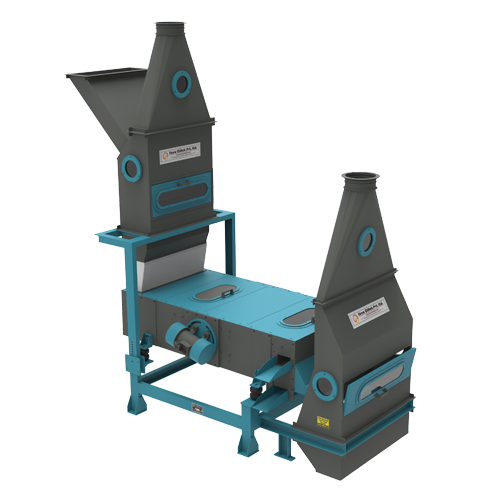

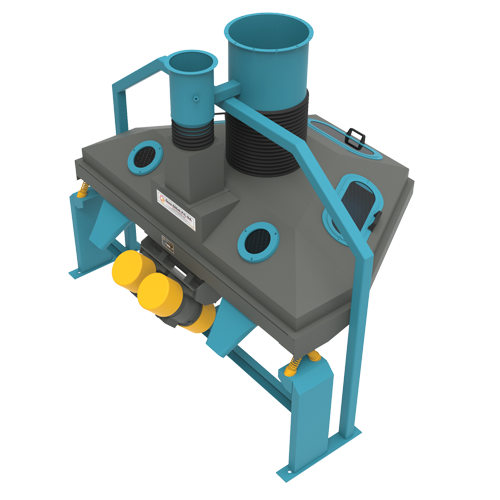

- Cleaning : Soybeans are thoroughly cleaned using seed cleaner and magnetic feeders to remove metal and impurities that could interfere with processing. Ferro Dry Destoner is basically used in the application of soya seed cleaning to separate stone, glass & other impurities present in the seed.

- Dehulling : The hulls are removed to increase protein content in the meal and enhance the efficiency of the extraction process.

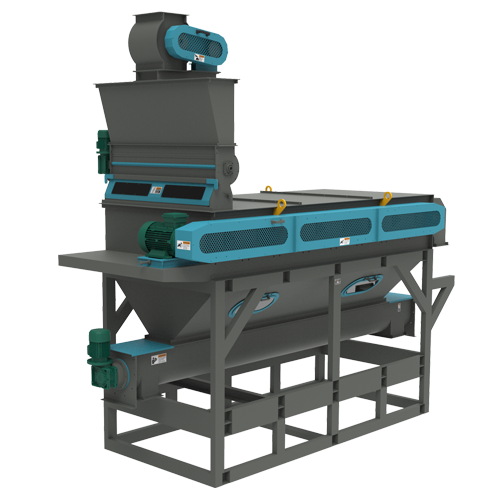

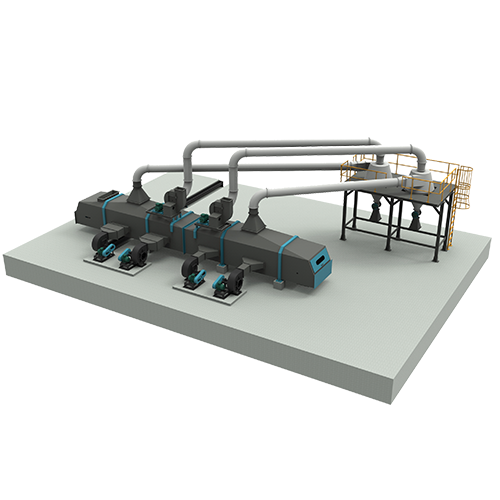

- Flaking : Using the FX Flaker Machine, the soybeans are turned into thin flakes, rupturing the cells and releasing the oil.

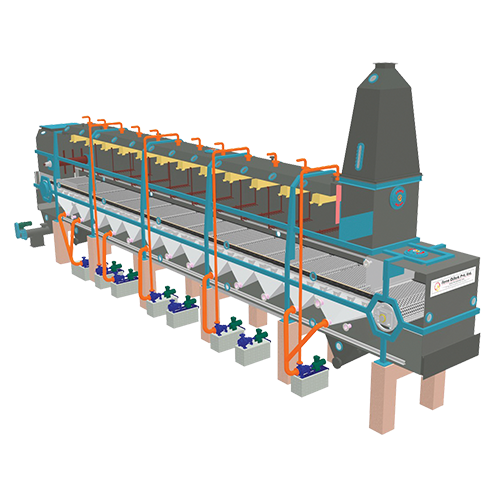

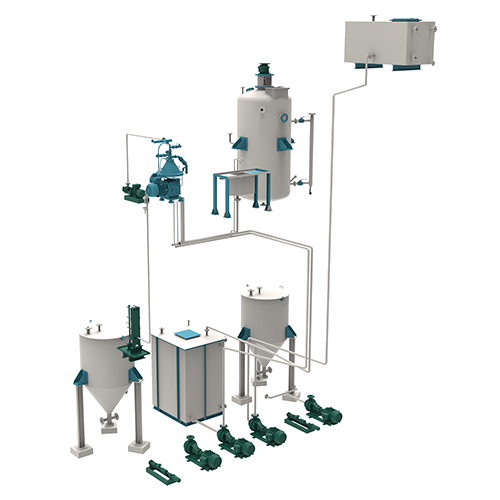

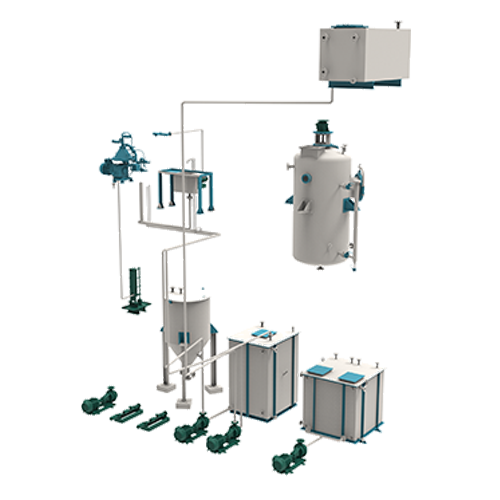

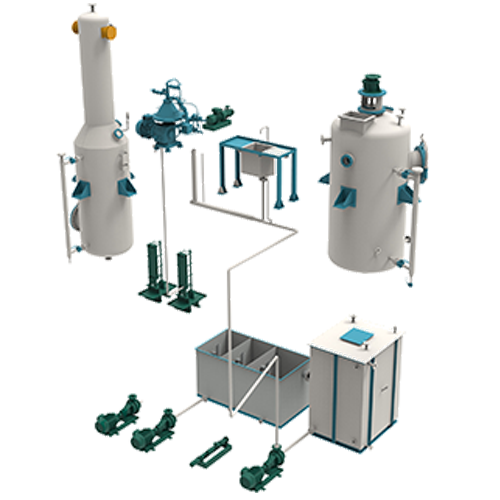

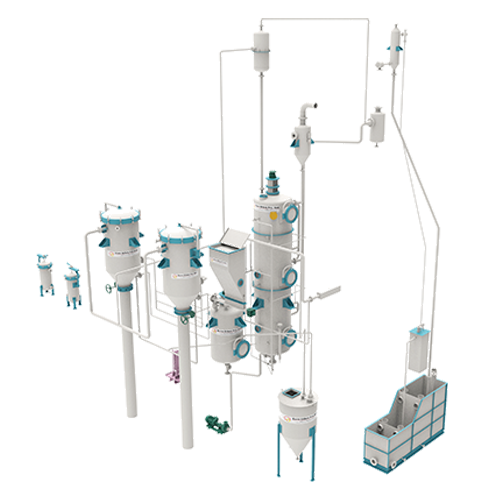

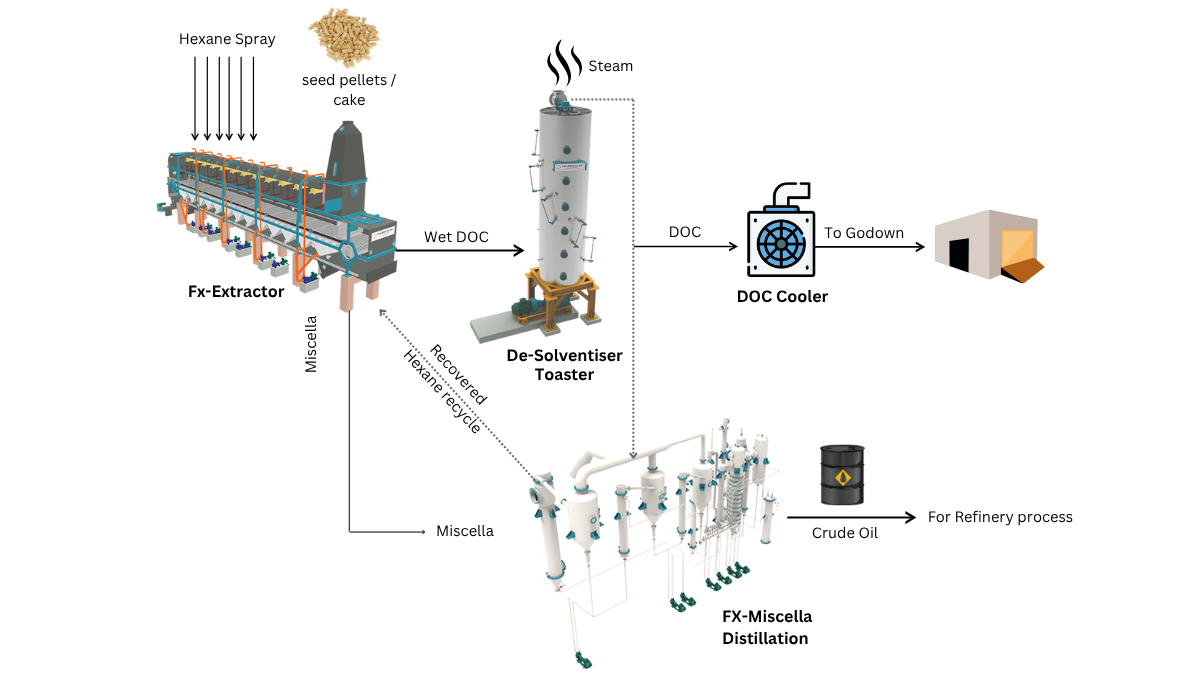

Extraction & Desolventizing

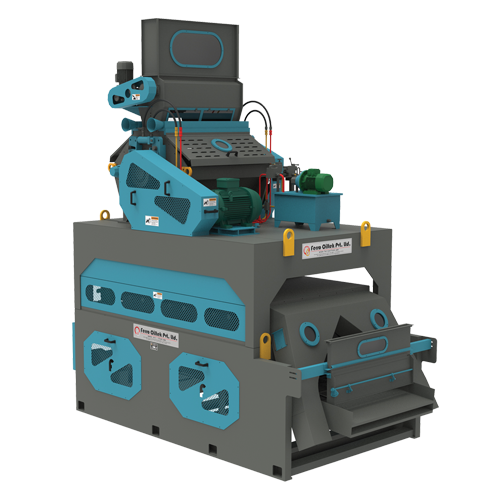

- Hexane Extraction : Solvents like hexane are used to efficiently extract soybean oil from the flakes. The process optimizes solvent use, bed depth, and contact time for maximum yield. The FX-Extractor ensures efficient extraction.

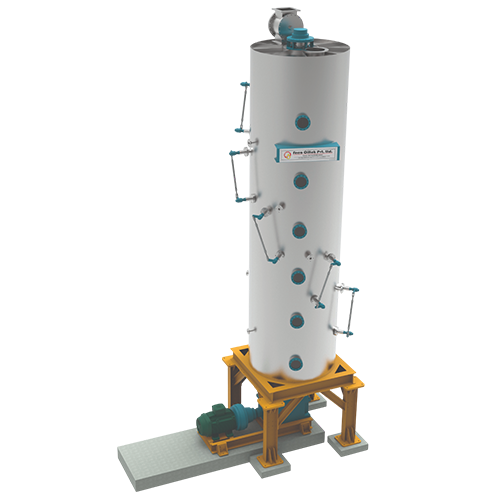

- Removing Solvents : Ferros De-Solventizer is used to recover residual solvent from the meal, the goal is also to toast the meal so that antinutritional factors are controlled, while a distillation system recovers solvent from the oil. Dryer cooler is for cooling the de-solventized and toasted material.

- By-Product : The desolventized meal become a high-protein meal.

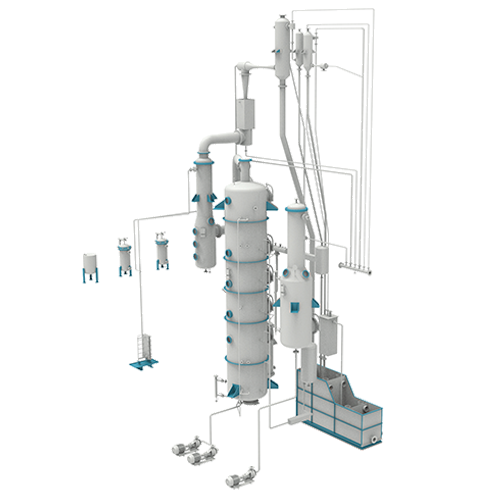

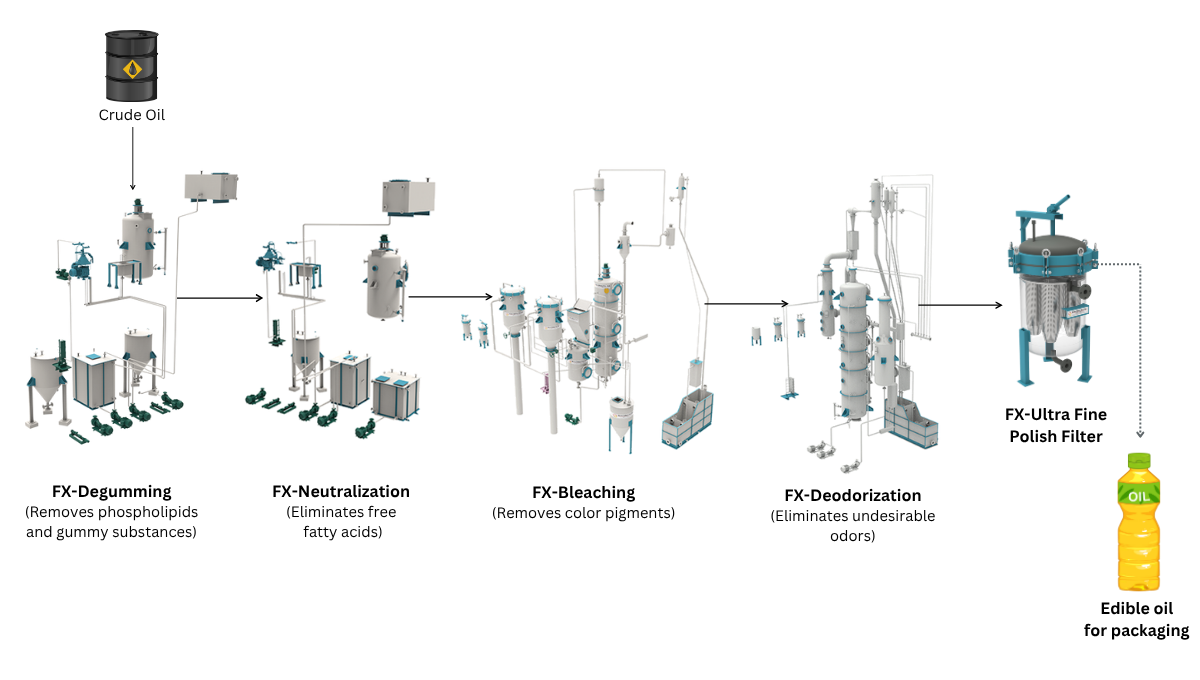

Oil Refining and Processing

- Refining : Extracted oil undergoes processes like degumming, neutralization, washing, bleaching, and deodorization to improve flavor, color, odor, and stability.

- Contaminant Removal : This step removes phosphatides, free fatty acids, and pro-oxidants for a cleaner, higher-quality edible oil.

Expert Answers for Smart Decisions

Get your edible oil plant with our solutions

Interested in this technology for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.