Mustard Seed Processing, Oil Extraction & Refining Plant

Mustard and Rapeseed are the second-largest oilseed crops in India, playing a pivotal role in the oil extraction industry. Traditionally, these seeds are processed through Ghani or expeller methods without de-hulling, resulting in oil with a darker color and a meal rich in crude fiber (about 70%). Since mustard/rapeseed contain around 20% hull portions, these byproducts contribute to the oil's dark and the meal's high fiber content, making it less ideal for food and feed. To address this, an integrated approach has been developed, designed to enhance the quality of both the oil and the meal. By removing the hulls, this process yields premium-quality mustard/rapeseed oil with a lighter color and a low-crude fiber mustard cake, perfect for use in food and animal feed applications.

Integrated Mustard/Rapeseed Processing: A Step Toward Premium Quality Oil and Meal

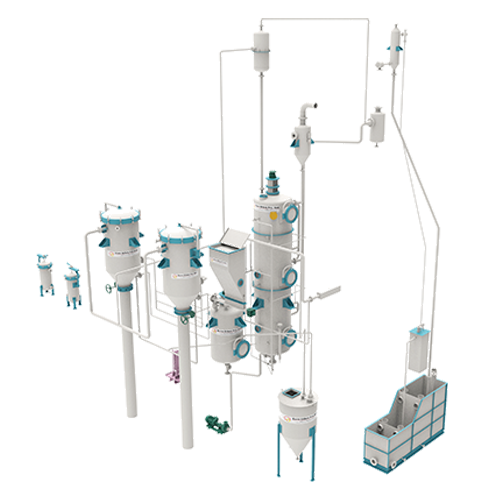

The integrated processing of Mustard/Rapeseed is a well-structured, multi-step process designed to maximize the quality of both oil and cake. Here's how it works:

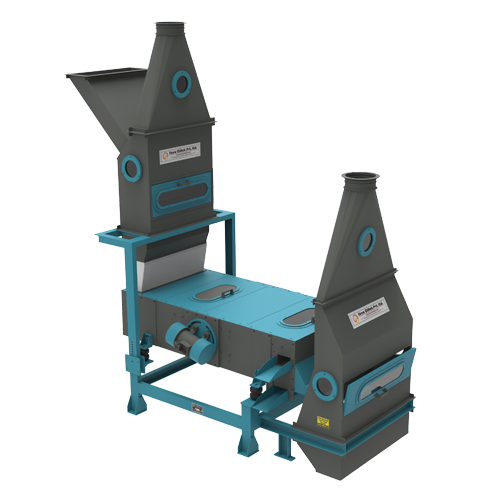

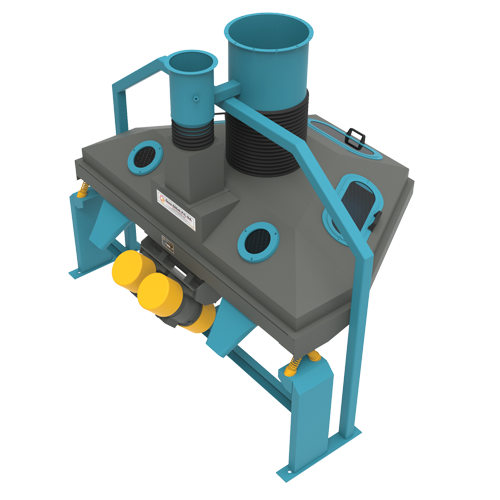

Seed Cleaning

In the mustard oil production process, seed cleaning is the initial and most essential step to ensure product purity and efficiency in later stages. The raw mustard seeds are carefully cleaned to remove impurities such as stones, dust, sand, broken seeds, plant residues, and other foreign materials. This is achieved using vibrating screens, air blowers, and magnetic separators that help segregate unwanted matter based on size, weight, and magnetic properties. A thorough cleaning process prevents machinery damage, improves oil yield, and ensures the extracted oil retains its natural aroma and nutritional value.

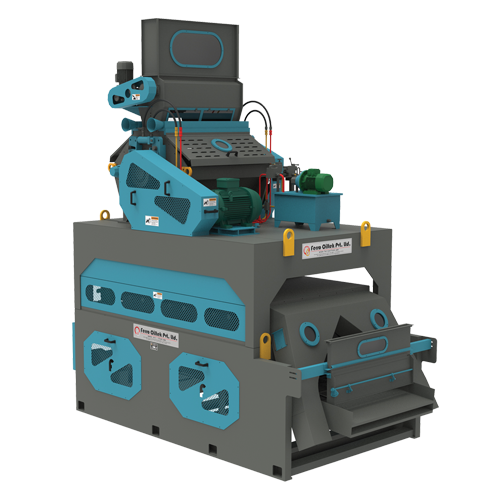

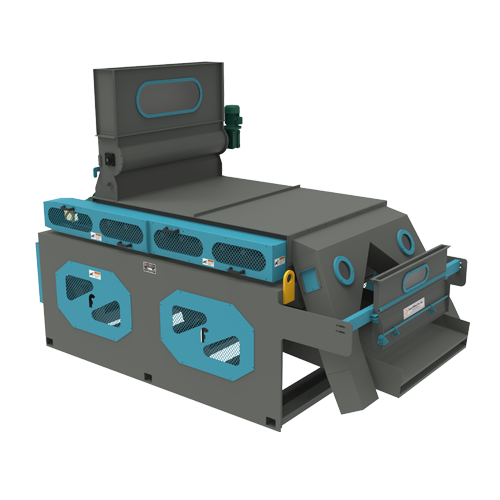

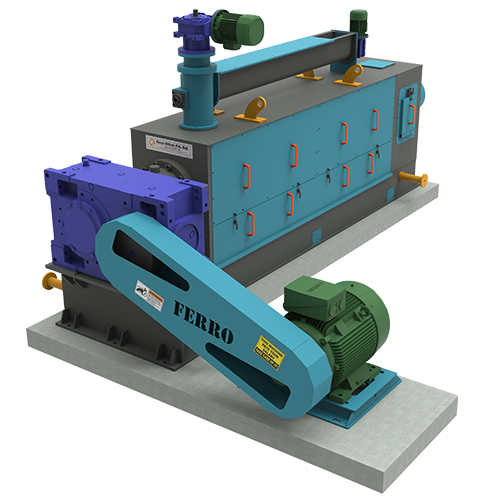

Mustard Seed Crushing/Grinding

After cleaning, the mustard seeds are passed through crushing or grinding machines to break them into smaller particles, facilitating easier oil extraction. The crushed seeds are typically passed through rollers or mechanical grinders that rupture the seed coat and release the oil-bearing cells. This step is vital as it increases the surface area of the seeds, allowing maximum oil to be extracted during the pressing or expelling process. Proper crushing ensures uniform particle size, leading to higher efficiency, better oil recovery, and enhanced quality of the final mustard oil.

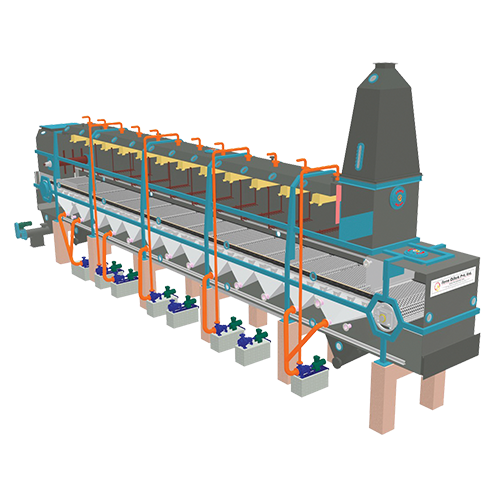

Oil Extraction

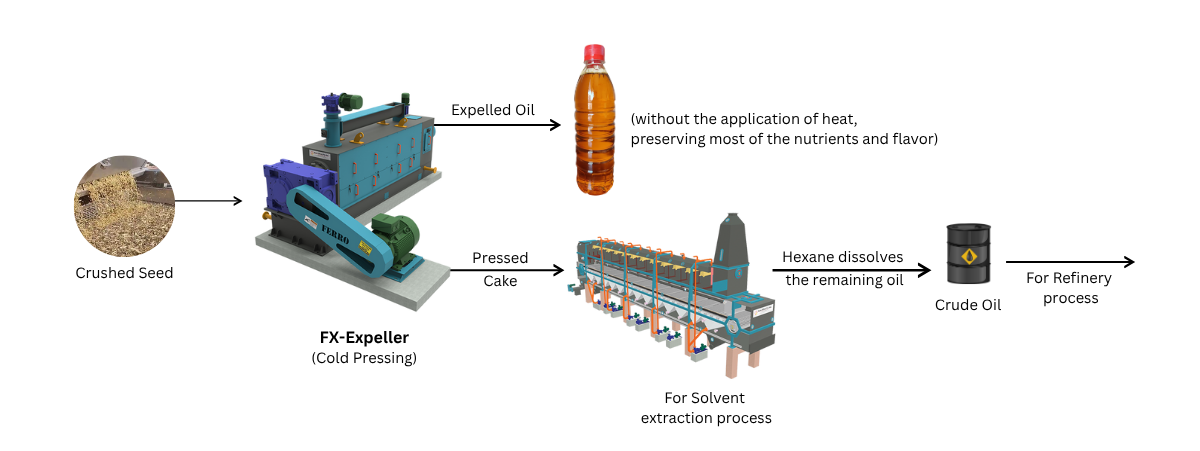

There are two main methods for oil extraction from mustard seeds:

- A. Cold Pressing (Expeller Pressing) Extract oil by mechanically pressing the seeds without the application of heat, preserving most of the nutrients and flavor.

- B. Solvent Extraction After the first step of pressing, the remaining cake (press cake) is treated with a solvent, typically hexane, which dissolves the remaining oil. The oil is then separated from the solvent, and the solvent is evaporated and recovered for reuse.

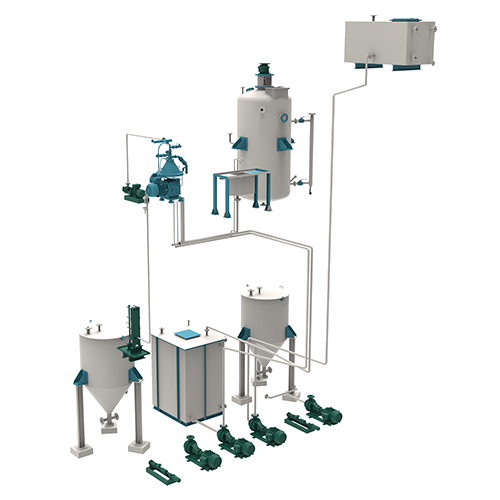

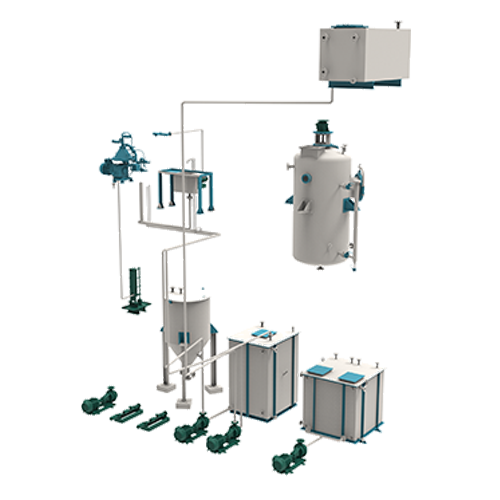

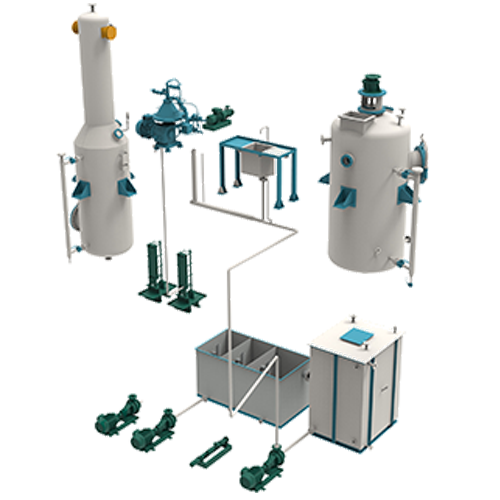

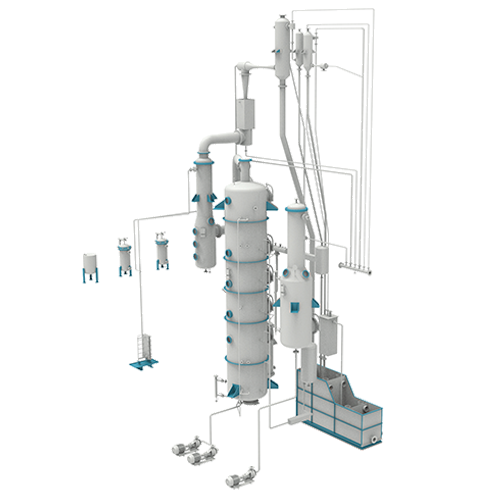

Oil Refining

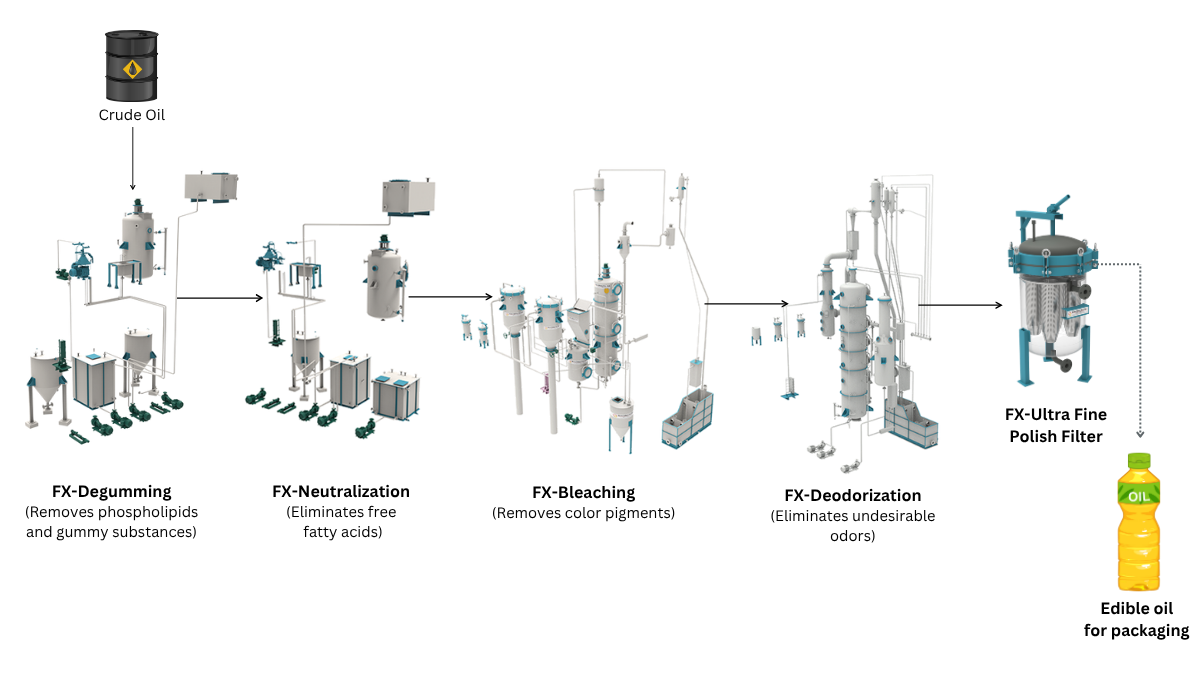

The crude mustard oil that is extracted needs to be refined to remove impurities, free fatty acids, color, and odors to make it safe and suitable for consumption. The Refining Process involves several stages to transform crude mustard oil into a high-quality edible oil.

The Refining steps include: FX-Degumming (remove phospholipids by using water or acid), FX-Neutralization (remove FFA by treating with an alkali), FX-Bleaching (remove colour pigments by treating oil with activated carbon or clay), and FX-Deodorization (eliminates undesirable odors & volatile compound by oil heated under a vacuum), FX-Winterization (remove waxes by oil is chilled and then filtered the solidified wax & fats).

Finally refined oil is further undergone through FERRO new design FX-Ultra Fine Polish filter to making ultra-pure polished oil for cooking.

Get your edible oil plant with our solutions

Interested in this technology for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.