Sunflower Seed Processing, Oil Extraction & Refining

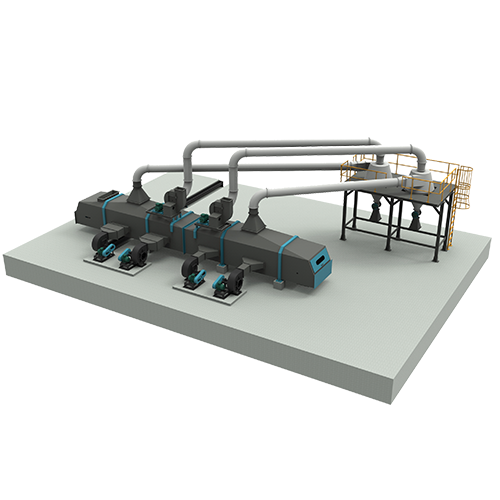

Ferro Oiltek’s Sunflower Seed Processing solution — engineered to deliver high-quality sunflower oil with exceptional yield and purity. Our turnkey systems cover the entire seed-to-oil workflow: cleaning, decortication, conditioning, pressing/solvent extraction, and refined oil production.

Sunflower seed (Helianthus annuus) processing is critical in today’s edible oil industry because of growing global demand for high-quality sunflower oil, rich in vitamin E and healthy unsaturated fatty acids. Efficient processing ensures minimal oil loss, high by-product value (meal, hulls) and consistent oil quality. With the right technology, you ensure cost-effective production, stable supply, and strong profitability.

Ferro Oiltek’s Sunflower Processing Technology Features

At Ferro Oiltek, our sunflower seed processing line offers:

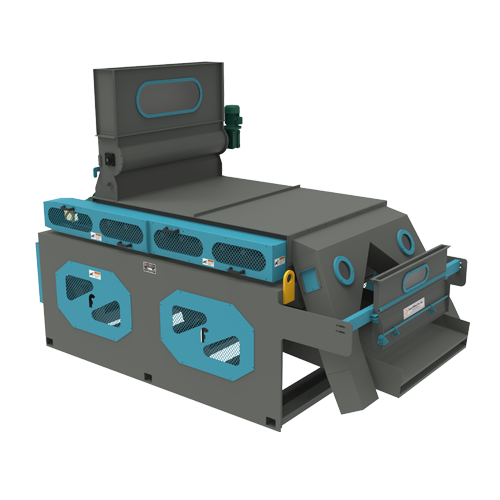

- Comprehensive Cleaning & Magnetic Separation – to remove impurities, stones and metallic contamination, protecting downstream equipment and oil quality.

- Decortication & Hull Separation – removes 20-30 % seed hulls to improve extraction efficiency and reduce fiber load.

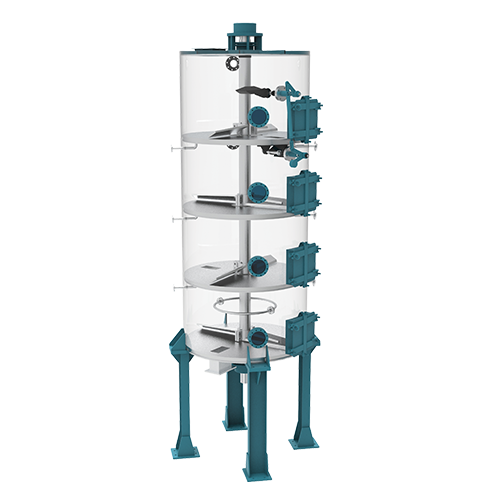

- Conditioning & Cooking Module – gently cooks the seed meats to optimal moisture and temperature for better oil release.

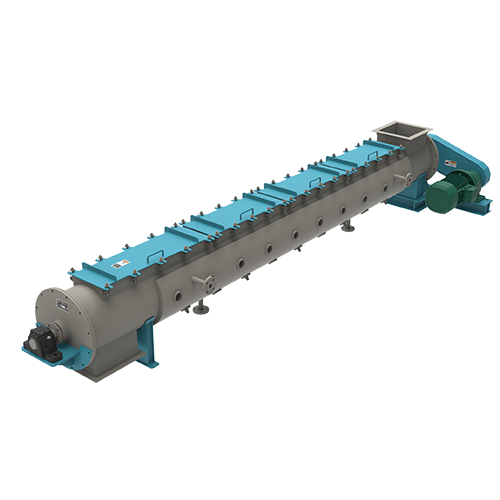

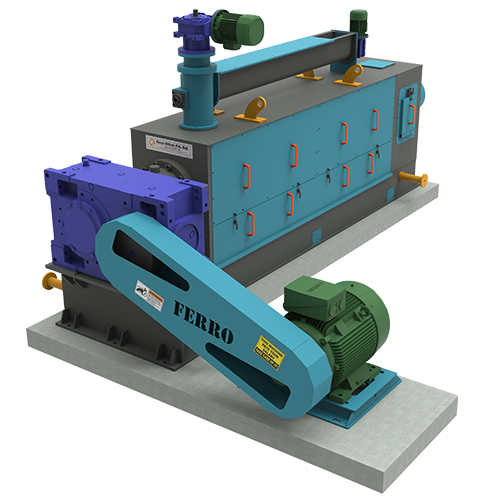

- Mechanical Screw Pressing followed by Solvent Extraction – for high-oil-content sunflower seeds, our dual-step process maximises yield: first mechanical expelling then solvent extraction of the expeller cake.

- Full Refining System for Crude Sunflower Oil – including degumming, neutralisation, bleaching, dewaxing, deodorisation, and ultra-fine polishing for premium edible oil.

- Automated Modular Design & Scalability – our plant solutions are customised for capacity, raw material variation and local operating conditions.

Applications & Benefits of Our Sunflower Seed Processing

Our portfolio is ideal for companies processing sunflower seeds for edible oil, meal for animal feed and hull separation. Key benefits include:

- Higher oil recovery from sunflower seeds, reducing residual oil in cake

- Enhanced meal value thanks to cleaner separation of hulls and lower fiber content

- Premium refined oil quality with better clarity, taste and shelf stability

- Reduced operating costs via efficient solvent recovery and energy-optimised design

- Flexibility to handle different sunflower seed varieties and processing capacities

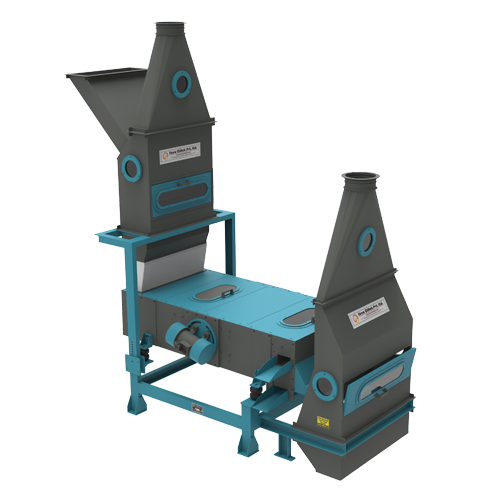

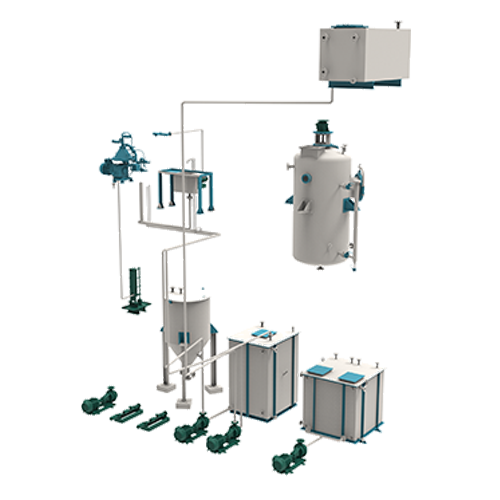

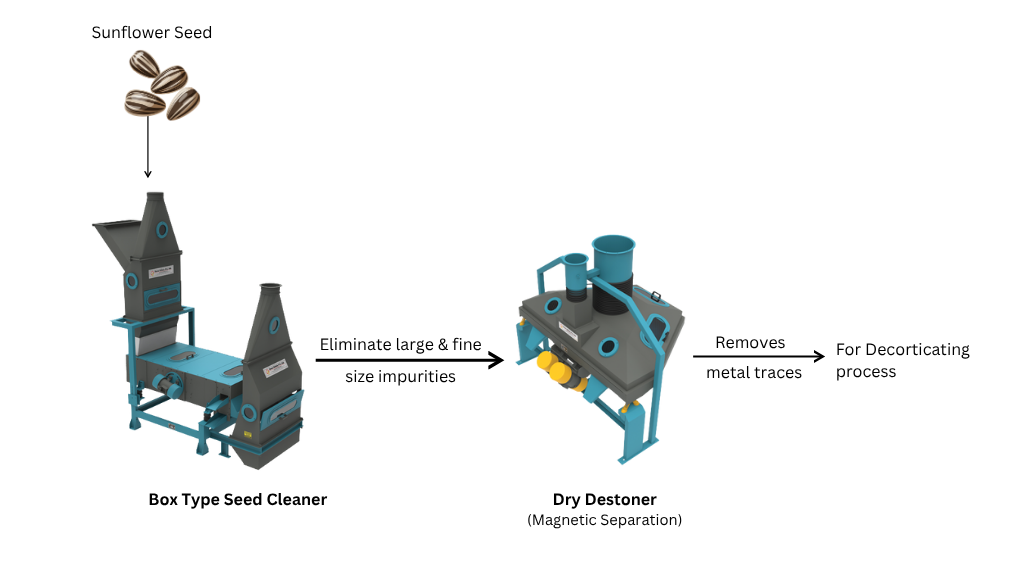

Cleaning Process

- Seed Cleaner : Ferro Box Type Seed Cleaner eliminate large & fine size impurities to ensure a clean, high-quality product.

- Magnetic Separation : Seeds are passed over magnetic feeder to remove metal traces.

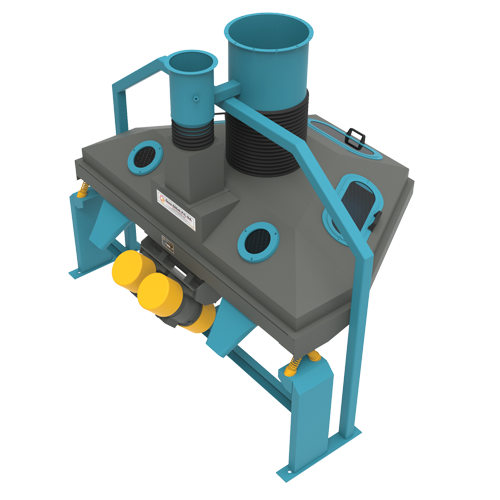

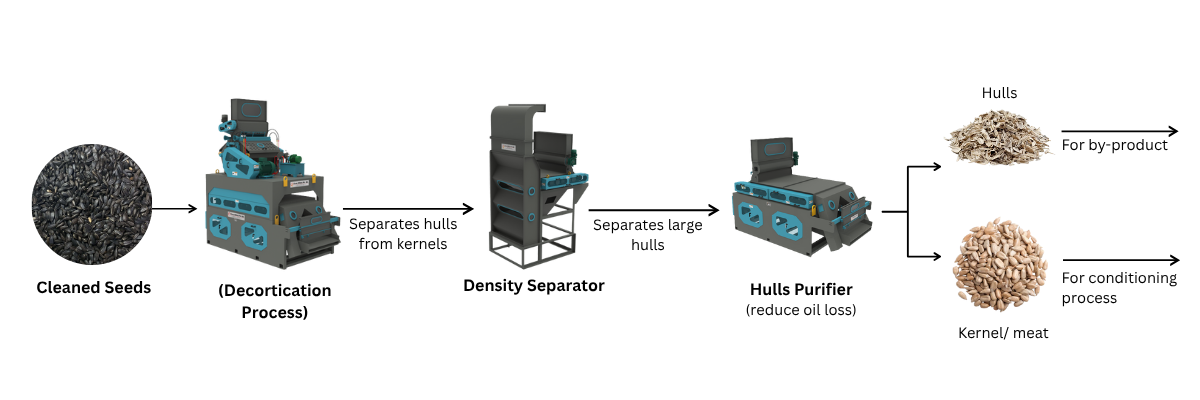

Decorticating

- Hull Removal : Seeds contain 20%-30% hulls, which are removed to improve oil quality and meal efficiency.

- Decorticator : The Ferro 48" Decorticator cracks seeds for hull removal, followed by a density separator and hull purifier to reduce oil loss.Cleaned linters are compressed into bales for sale.

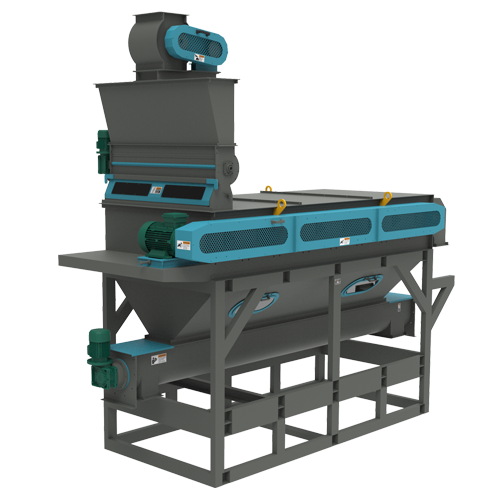

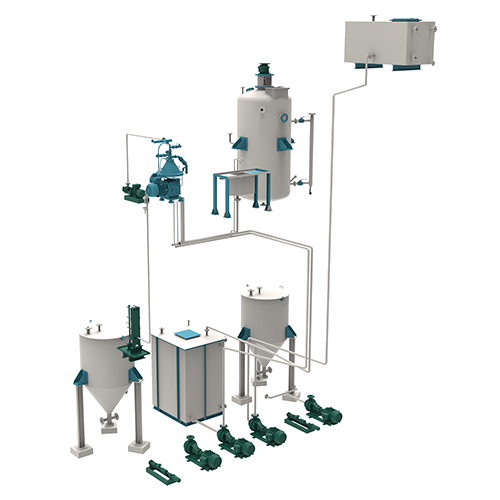

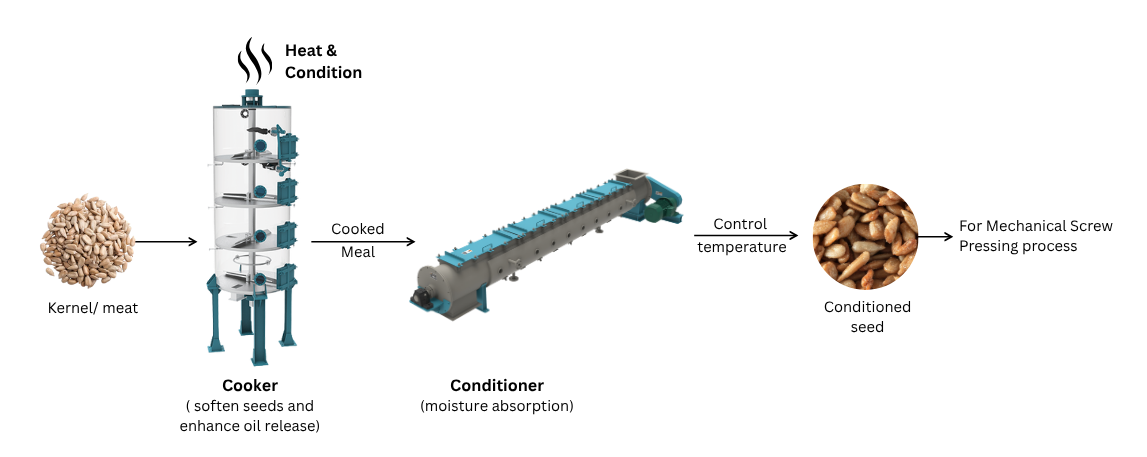

Conditioning

Cooking & Conditioning : The meat is cooked to facilitate oil extraction, while during oil pressing, some impurities are also released with the oil, and they should be removed before the oil can be edible.

Related Products :

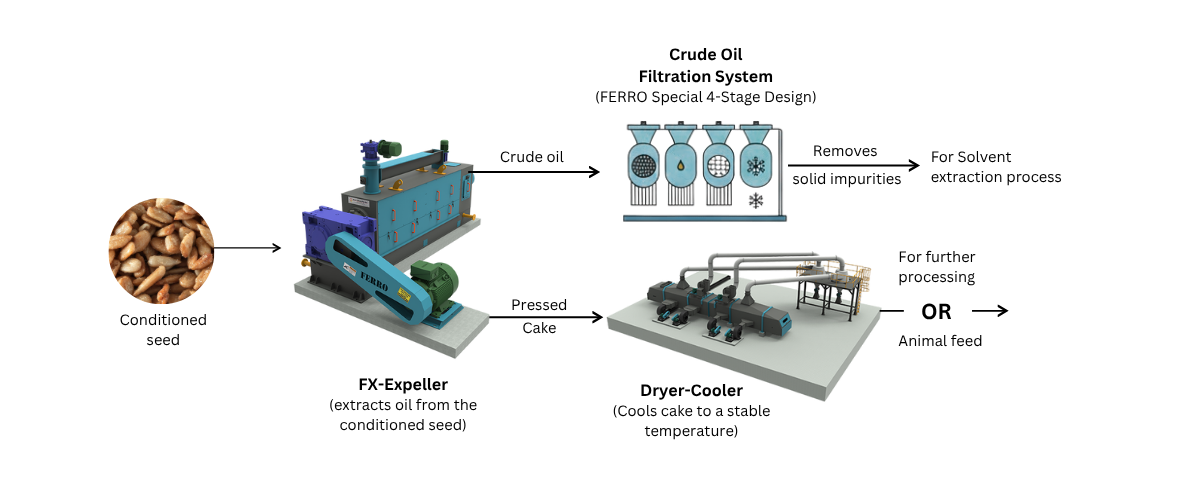

Mechanical Screw Pressing

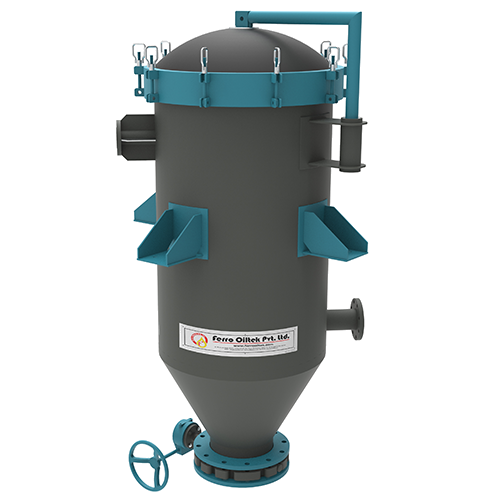

Due to high oil content sunflower seed the oil extraction been proceed through two steps of sunflower seed oil extraction, first oil seed undergoes with mechanical screw press followed by second step solvent extraction, Under the Sunflower seed expelling section, the key equipment's FX-Expeller, crude oil filtration equipment's (FERRO special design 4 stage filtration) and FX-cake cooler plays a crucial role to maximize oil yield, ensure product quality, and improve operational efficiency.

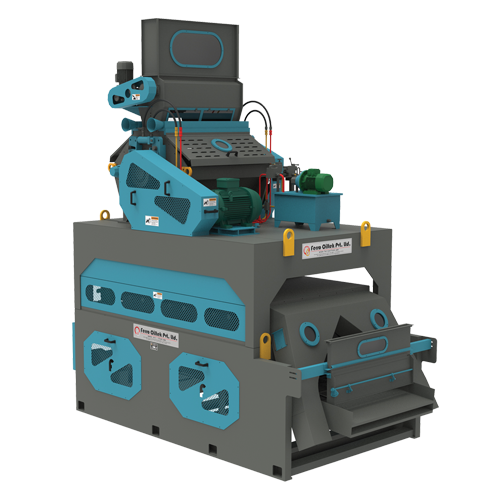

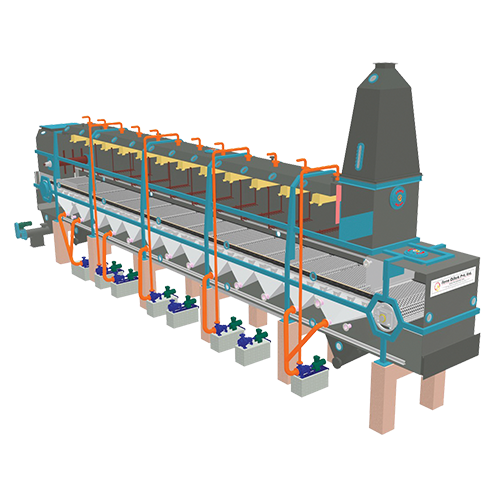

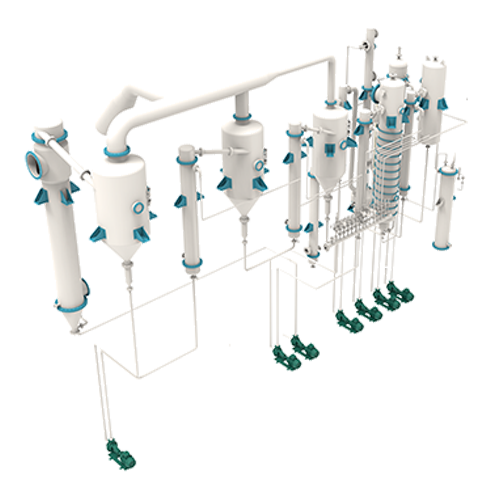

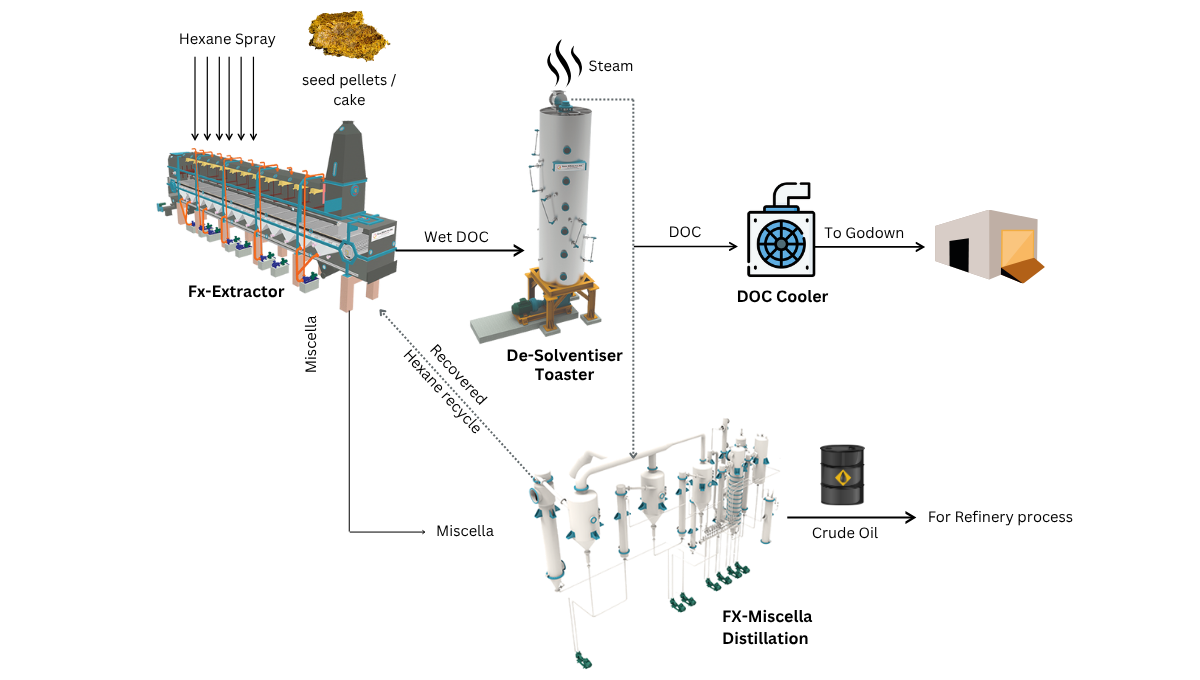

Solvent Extraction

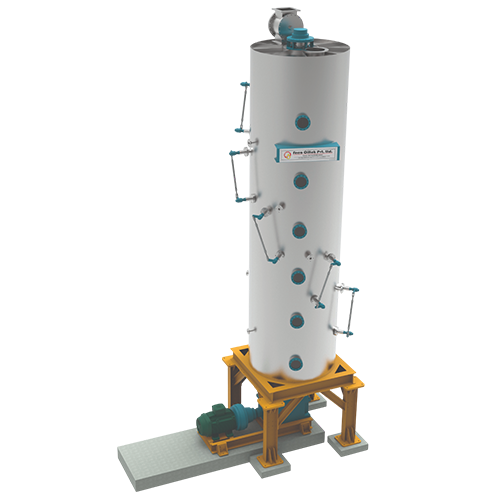

The solvent extraction is a method used to extract the residual oil from expeller outlet cake. It involves FX-Extractor equipment using a solvent (typically hexane) to dissolve the oil from the seed's pallets/ cake, followed by separating solvent by FX-Miscella Distillation and FX-DeSolventiser toaster to recycle hexane by making process efficient with achieving best results of minimal hexane losses.

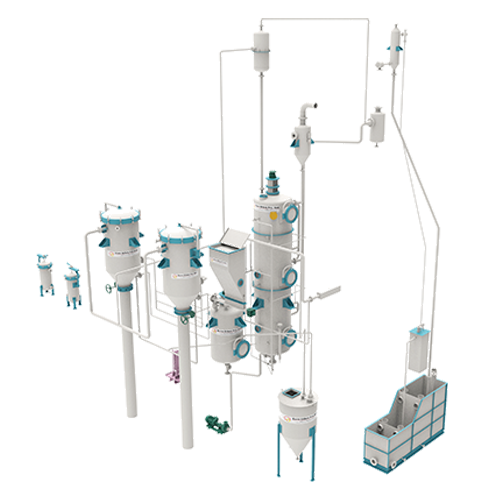

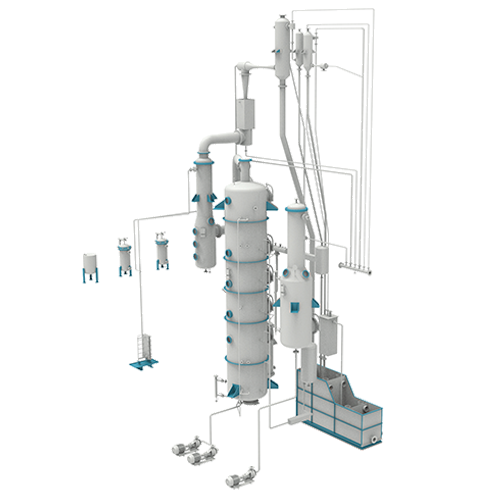

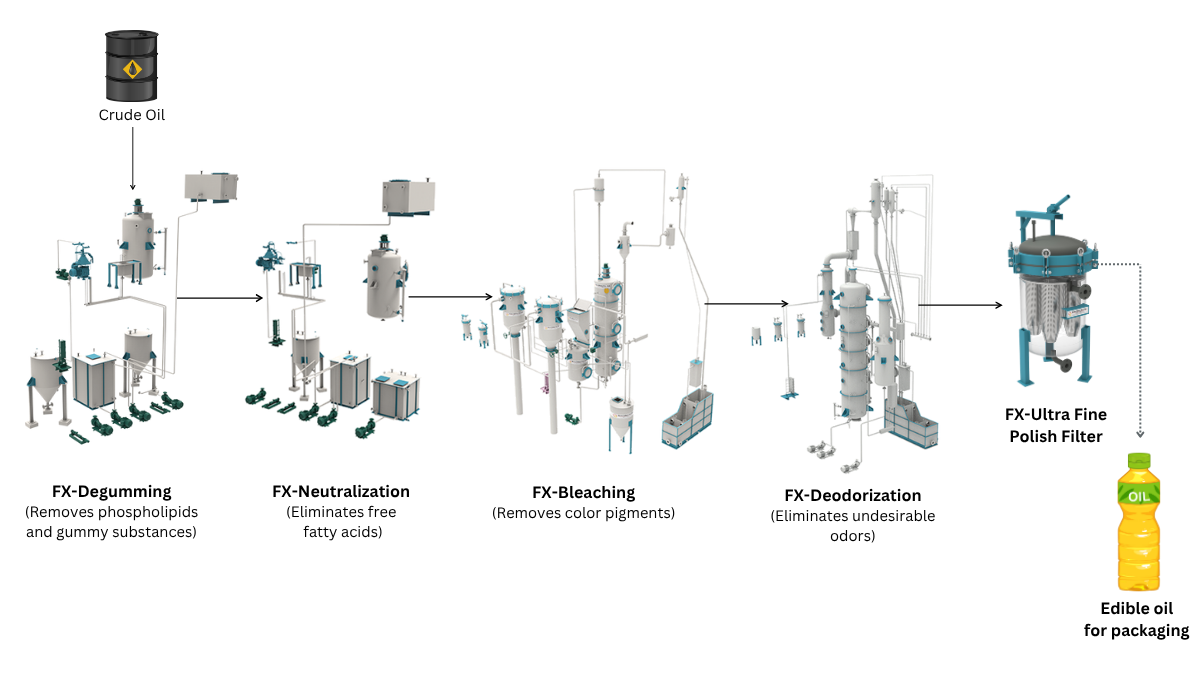

Sunflower Refinery

The Sunflower Seed Edible Oil Refining Process involves several stages to transform crude sunflower oil into a high-quality edible oil. Here's a detailed breakdown: It involves multiple stages, including FX-Degumming (remove phospholipids by using water or acid), FX-Neutralization (remove FFA by treating with an alkali), FX-Bleaching (remove colour pigments by treating oil with activated carbon or clay), and FX-Deodorization (eliminates undesirable odors & volatile compound by oil heated under a vacuum), FX-Dewaxing (remove waxes by oil is chilled and then filtered the solidified wax & fats). Finally refined oil is further undergone through FERRO new design FX-Ultra Fine Polish filter to making ultra-pure polished oil for cooking.

Expert Answers for Smart Decisions

Get your edible oil plant with our solutions

Interested in this technology for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.