Cotton Seed Processing, Oil Extraction & Refining Plant

Cotton Seed Processing, Oil Extraction & Refining Plant

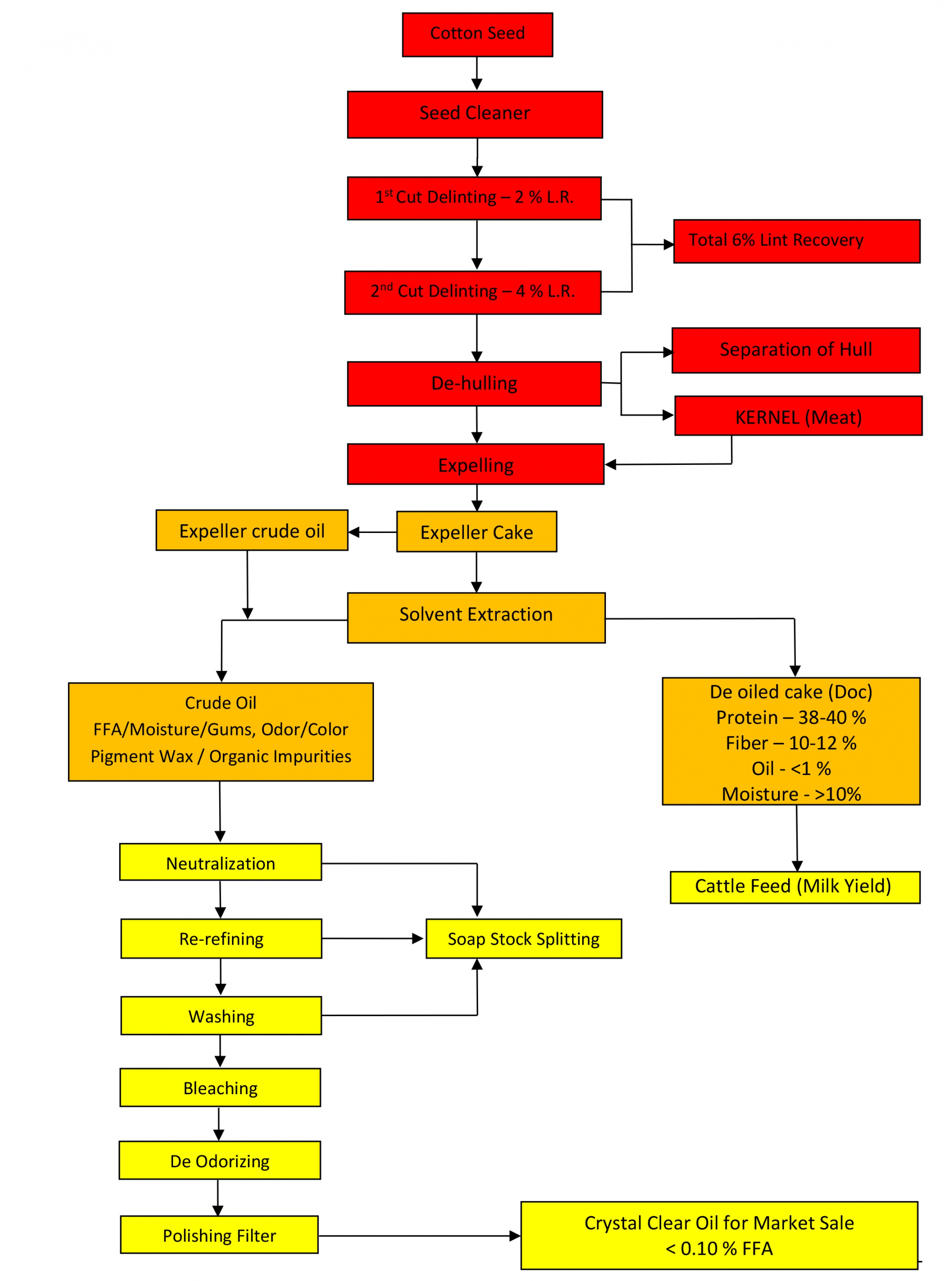

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton Seed Processing results in extraction of nearly entire cottonseed oil, while the oil cake obtained by traditional method still contains about 7% residual oil. This high residual oil is not required by the animals but ironically much in demand because of misconception among the dairymen. The cottonseed meal obtained through scientific method contains negligible oil and has very high by-pass type protein content of around 40 to 42%. And as we know the cattle only need to have more protein in meal not oil.

Process Description of scientific processing of Cotton Seed Processing: - In scientific process of Cotton Seed Processing first cotton seed is sent for cleaning operation that is in seed cleaner all impurities are removed (like; unginned cotton & all type of foreign partials etc.), then cleaned seed is sent to Delinting operation here the short fiber which is there on the surface of cotton seed known as linters is removed by Delinting operation and these delinted linters need to be cleaned so it sent for lint cleaning operation where small hulls and motes come along with linters are separated & then sold out as a product in the form of bales which is formed in a bailing press machine.

In Cotton Seed Processing, after delinting operation we get a delinted seed. After Delinting operation we get a delinted seed. This seed is then sent it for decorticating operation that is, here in decorticating section cotton seed hulls & meat is separating from each other with the help of series of machines;

1. Decorticator machine

2. Density separator machine

3. Hulls Purifier machine etc.

After these three stage operation in Cotton Seed Processing we get separate hulls & meat. Then the meat is sent it for further process that is for seed preparation, oil extraction process, refinery process & hulls that we can sell for further process or we can used it as a boiler fuel.