Rice Bran Oil Extraction Technology

Rice Bran Oil Extraction Technology

Rice bran Oil is on hot sale in recent years and was recommended to be one of the best and healthier cooking oil and frying oil. It is praised for being versatile and having a neutral taste and stable when exposed to high temperatures. Many people prefer it for frying, BBQs, salad dressing and baking. Rice bran oil, compared to the other vegetable oils sold commercially, it has more Plant Sterols (Phytosterol) and Gamma- Oryzanol that has the ability to reduce LDL Cholesterol. Now, with the increasing awareness of rice bran oil, rice bran oil processing has been a hot investment business.

Rice Bran oil Processing plant adopts expansion technology, which increases extraction ef?ciency, reduces residual oil rate and improves the quality of the extracted oil. Rice bran oil extraction plant adopts negative pressure evaporating system, having the low evaporating temperature, the extracted oil has good quality and shallow color, saving steam consumption, it also adopts mineral oil system to reduce solvent consumption.

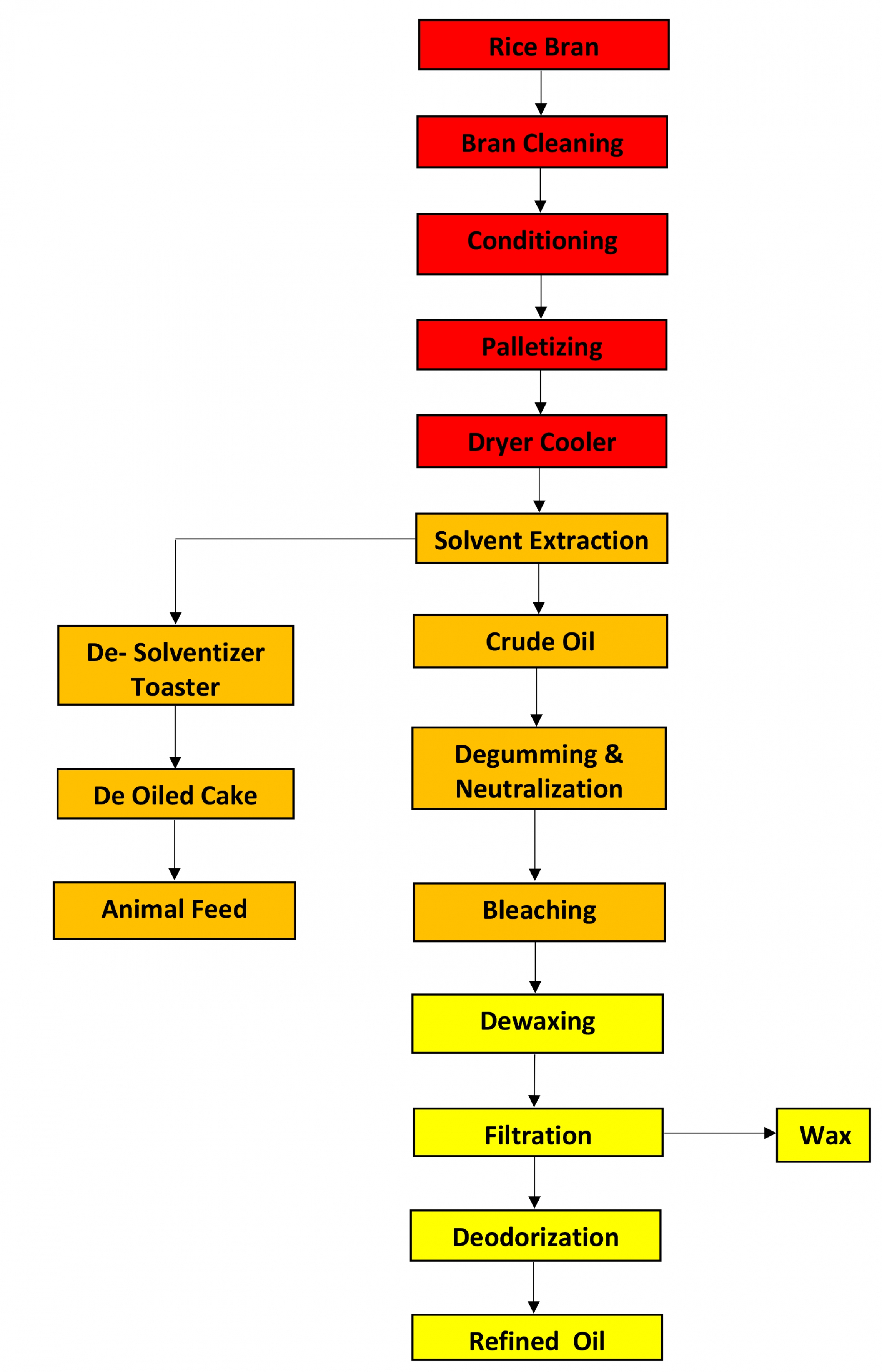

Preparatory & Pelletising : First the rice bran enters the cleaning screen in the rice processing oil plant to remove the impurities. Then magnetic separator is adopted to remove the iron impurities. Iron impurities can cause damage to the expander or pelletiser and influence the expansion effect. The rice bran goes through rice bran & broken rice separator to remove broken rice and whole rice. This process can ensure normal operation of the rice bran oil processing plant, reduce residual oil rate in the meal, reduce solvent consumption and increase the oil yield. The broken rice can be used for sugar and liquor making. Conditioning is to preheat the rice bran and adjust the moisture content. The moisture content can decide the elasticity and plasticity of the expanded materials. Preheating can improve the expansion effect and increase capacity. The rice bran enters the conditioner for conditioning process in the rice bran oil production line.

The conditioned rice bran enters the rice bran through pelletiser or expander and direct steam is injected. By the rotating of the main worm shaft, the materials are pelletized, heated, sheared and kneaded, the temperature and pressure, the moisture evaporates rapidly and the materials expand and form the porous pellets. The expanded materials have high temperature and high moisture content and shall be dried and cooled to meet the requirement of the extraction process. Usually Pneumatic dryer is adopted in the rice bran oil processing plant for the drying and cooling of expanded rice bran.

Solvent Extraction Process : The Expanded Rice Bran pellets enters the extractor or loop extractor in the rice bran oil extraction plant to extract the oil with a solvent. The Drained wet meal is sent to the desolventizer by the solvent sight redler conveyor. The thick miscella is pumped into the miscella centrifugal separator and continuous miscella filter to remove the solid impurities and finally pumped into the miscella holding tank. The solvent containing wet meal discharged from the oil extractor enters the desolventizer to separate the solvent from the meal. The mixed vapor from the desolventizer in the rice bran oil plant enters the shell pass of first long tube evaporator as the heat source.

The miscella from the miscella holding tank enters the first evaporator, the second evaporator and the disk stripping column in the rice bran oil plant to separate solvent and crude rice bran oil. The solvent vapor enters the condensing system. The crude oil enters the crude oil holding tank. The rice bran oil extraction plant adopts negative pressure evaporation technology, saving steam consumption and the extracted crude oil has good quality.

Refining of Rice Bran : Rice bran oil is normally refined by physical methods to keep the oryzanol in the refined oil. Because in chemical refiing process, oxyzanol get distributed by alkali reaction. The operation for physical rice bran oil refiing are as follows:

- Hot Water De-gumming

- Bleaching (PPE)

- Dewaxing

- Post Bleaching (Optional)

- Deodorization

- Winterization (Optional)