FX-PCAC: Air Cascade Pre-Cleaner

This machine is a combination of density separator and basket beater separator for better Read More

SEED PROCESSING

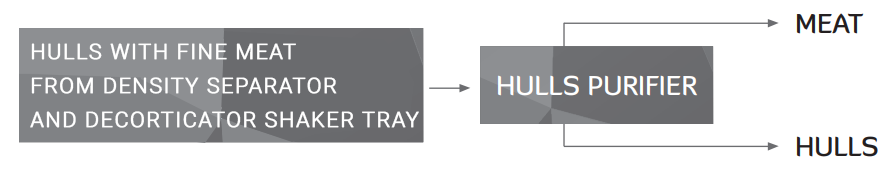

It is mainly designed for separation of hulls & meat. Hulls purifier produces minimum oiled hulls by removing fine meats from the hulls. It is capable of handling capacity up to 200 tons per day (on white seed basis). Machine consists of 10 basket beaters, mounted above shaker tray.

HULLS PURIFIER OPERATION :

The mixture of hulls and fine meat which is coming from decorticator & density separator is fed into the hulls purifier machine. Hulls is passed through 10 cylinder basket beater where fine meat which is sticky with hulls is separated by beating and this fine meat drop down from screen of basket into the shaker tray and forwarded to meat conveyor & hulls move forward at the end of beater. All hulls collected by two way nozzle and dropped into the hulls conveyor.