FX-PCAC: Air Cascade Pre-Cleaner

This machine is a combination of density separator and basket beater separator for better Read More

SEED PROCESSING

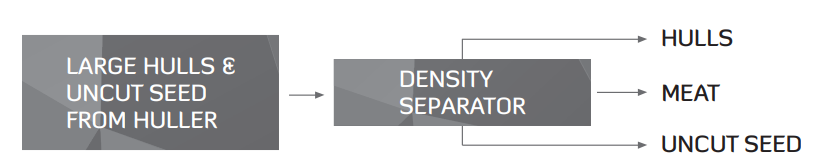

Ferro Density Separator is specially design to allow complete separation of a variety products based on their density. It is the combination of density separator & basket beater separator for better operational results & low oil loss in hulls. The density separator consists of variable speed regulating feeder driven by suitable gear motor. The specially designed inside structure is suitable for separating the uncut seed, large hulls, and meat powder. Equipment is capable to maintain low oil in hulls.

FERRO DENSITY SEPARARTOR OPERATION:

Mixture of large hulls, meat & uncut seed fed into the density separator for separating on the basis of density that all are coming out from decorticator machine. First the mixture is fed into 6 stage basket beaters through variable speed regulating feeder, by beating operation sticky meat separated from hulls & drop down by screen of basket.

Remaining hulls & uncut seed are move forward into zig zag chamber, where uncut seed drop down because of high density, and low density hulls removed from top of zig zag chamber.

Separate out fine meat from basket, meat mesh gets collected in common meat conveyor. Further uncut seeds returns to decorticator and hulls which is pneumatically lifting, that goes for final hulls purifier machine.