Sunflower Oil Seed Technology

Sunflower Seed Processing, Oil Extraction & Refining Plant

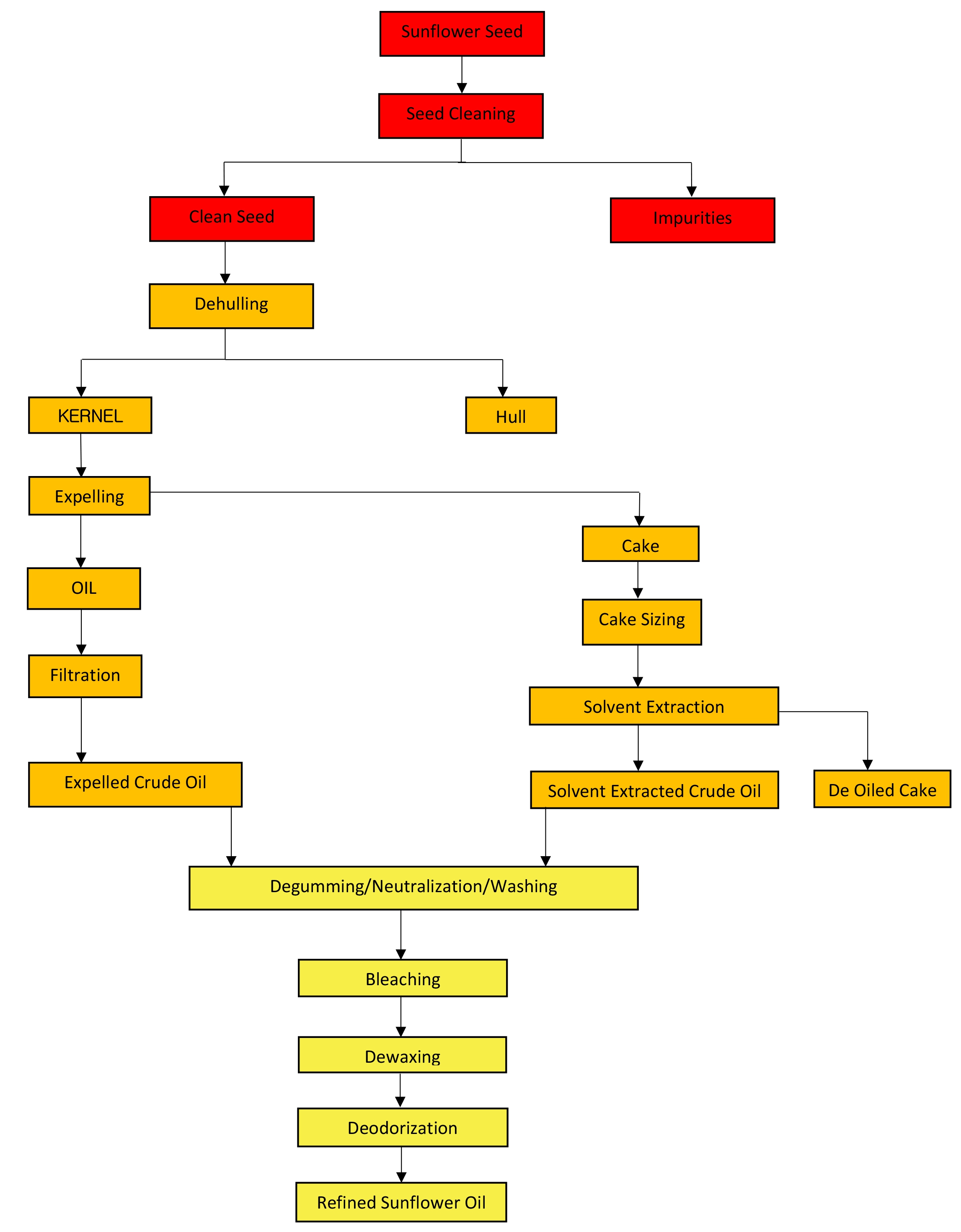

In Sunflower seed processing, seed oil is cold-pressed and entails minimal processing to produce a light, flavorful oil suitable for some cooking needs. In Sunflower seed processing, seed oil manufacture involves seed cleaning, seed de-hulling, seed grinding, seed pressing and extracting crude oil, crude oil refining.

- Cleaning:In Sunflower seed processing, the prepared sunflower oil seeds are passed over magnets to remove the trace metal before de-hulled; and passed the special cleaning machine to remove other foreign matters.

- De-hulling: Sunflower seeds from the oil-type contain about 20%-30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. In Sunflower seed processing, De-hulling is done when the seed has a moisture content of 5% after cleaning. The usual process consists of cracking the seeds by the mechanical action. Ferro 48" Decorticator, where the further process is followed by density separator and hullls purifier to achieve minimum oil left in hulls. Some oil sunflower seeds have thin hulls that are difficult to remove, so they can be free from de-hulling to avoid oil loss.

- Grinding: In Sunflower seed processing, the prepared sunflower oil seeds are passed over magnets to remove the trace metal before de-hulled. For more surface area to be pressed, the de-hulled seeds are grounded into coarse meal of proper consistency by mechanized grooved rollers or hammer mills. Then the meal is heated to facilitate the oil extraction. While during oil pressing, some impurities are also released with the oil, and they should be removed before the oil can be edible.

- Pressing: In Sunflower seed processing, the heated meal is continuously fed into a screw press. Pressure generally increases from 68,950 to 206,850 kilopascals as the oil is squeezed out through the slots in the barrel and is recovered.

- Extracting additional oil with solvents: The remaining oil cake in the press can be processed by solvent extraction to get maximum yield. A volatile hydrocarbon (the most commonly used one is hexane) dissolves the oil out of the oil cake, and then the oil is recovered by distilling the solvent out, and then the solvent passes through the matter to be collected at the bottom.

- Removing solvent traces: 90% of the solvent remaining in the extracted oil simply evaporates and it is collected for reuse. The remaining solvent is regained by the use of the stripping column. The oil is boiled by steam, and the lighter solvent floats upward, as it condenses, it is collected at the same time.

- Refining the oil: Refining the oil is to remove color, odor and bitterness. Refining involves heating the oil to 40°C -85°C (107-188°F) and mixing an alkaline substance such as sodium hydroxide or sodium carbonate with the oil. Then soap forms form the undesired fatty acids and the alkaline additive, and usually it is removed by centrifugal process. The oil will be further cleaned to remove soap traces and then dried.

- Physical Refining : Ferro has also developed physical refining process for sunflower oil refining whereas no harmful chemicals are used, the complete FFA is removed with the help of high retention distillation, also called as physical deodoriser. The free fatty acids are collected and sold for oleo chemical industry.

The oil is also de-gummed at this time by treating it with water-heated steam of 85°C -95°C (188-206 degree Fahrenheit), or water with acid. Most of the gum is the phosphatides to be precipitated out, and the dregs are removed by centrifugal process. Oil that will be used in cooking is then bleached by filtering it through fuller’s earth, activated carbon, or activated clay that can absorb some pigmented materials from the oil. By contrast, oil that will be refrigerated (for use in salad) is rapidly chilled and filtered to remove waxes. This procedure is to ensure the oil will not partially solidify in the refrigerator. The final process is the deodorization of the oil, in which the steam is passed over hot oil in a vacuum at 225°C -250°C (440-2485°F) to distill the volatile and odour components from the oil. Typically, to avoid the trace metals that might promote oxidation within the oil and hence shorten the oil’s shelf-life, as sunflower oil naturally contained wax, lecithin is treated by dewaxing operation whereas the oil is further clarified by filtration. If oil has to be marketed in very cold region, winterization process can be used as well. - Packing the oil: In Sunflower seed processing, pure oil is measured/ packed in clean containers, and the usual ones are bottles for domestic sale, glass bottles for exports or domestic sales in specialty stores, or cans for exports.