FX-PCAC: Air Cascade Pre-Cleaner

This machine is a combination of density separator and basket beater separator for better Read More

SEED PROCESSING

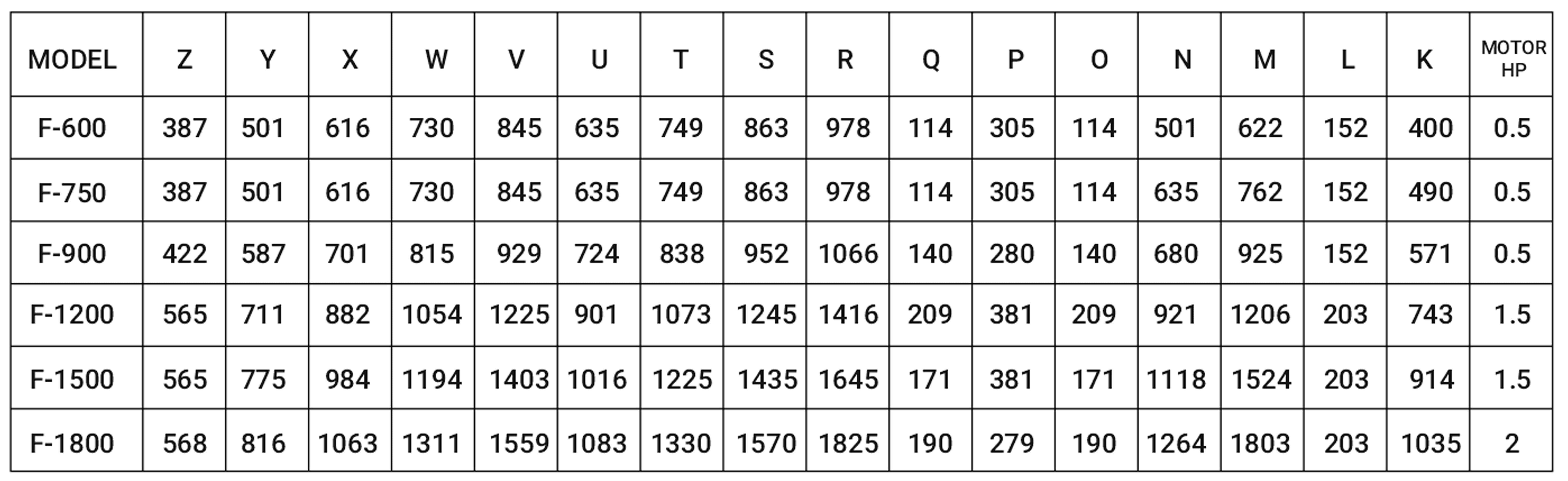

FERRO provide vibro separator for separations of dry & wet material. The vibro separator is suitable for all types of screen operations with below stated four broad categories. Dry classification, Solid / Liquid separation and Solid classification. Our Vibro Separators are designed to provide optimum performance. We Offers 6 different model Vibro Separator F-600, 750, 900, 1200, 1500, 1800 etc. And also we offered with MOC of SS-304, SS-316, SS316L, and Carbon Steel as per customer requirement. On Special request, MOC of non-ferrous can also be provided. All Ferro separators are backed by a full technical advisory service help to solved separation problem in industry.

OPERATION OF VIBRO SEPARATOR :

The material is fed on the center of the top screen and the bigger/oversized material is moved by the Multiplan motion to the periphery of the screen to be discharged through a tangential outlet. The undersize particles or liquids passes through the screen to produce fine sized fraction or clarified liquid.

1. Chemicals separation: Polyvinyl Chloride, Melamine Phenolics, cellulose acetate, polystyrene, detergents, caustic soda flake, titanium dioxide, calcium carbonate silicon carbide, alum etc.

2. Dry separation/ classification: Separation of particles having different shapes & sized fraction. Pulps and Wood Products, Animal Feeds, Grains, Cosmetics, Tea, Petrochemicals, Foods, Pharmaceuticals, Fertilizers, Ceramics & Abrasives

3. Solid/liquid separation: Foods separation from expeller out crude oil, Dewatering and removal of Solid particles from liquid medium.

Paper & Pulp, Foods, Ceramics, Minerals, Waste Disposal